As an important branch of the three major categories of foam ceramics (alumina, silicon carbide, and zirconia), alumina ceramic foam is also the earliest used ceramic foam. It is widely used in the aluminum and alloy casting industry.

At present, with the continuous improvement of the performance requirements of aluminum and aluminum alloy products, new requirements have been continuously put forward for the filtration of aluminum liquid. It is required to have high purity, less floating impurities, and smooth flow rate of the aluminum liquid, so that the casting aluminum products have better physical and chemical properties and machining performance, so as to meet more demanding conditions and extend the service life.

The development of ceramic foam filters has greatly improved the qualification rate of finished metal smelted products, and their product performance has also been greatly improved. Aluminum casting is one of the most widely used industries of ceramic foam filters. Its function is to make the turbulent and tumbling molten metal pass through the ceramic foam filter into a stable, uniform and clean molten metal. Thereby, the rate of casting rejects caused by casting defects such as non-metallic inclusions is greatly reduced, and production costs are saved.

Since 2012, AdTech has focused on R&D, production, and sales of adsorptive ceramic foam filter (CFF) used in aluminum alloy casting. AdTech’s ceramic filter plate technology has been widely accepted by the market and applied to multiple series of aluminum alloy products: PS for printing High-precision filtration and purification of cast aluminum alloys such as plate base, canning materials, elastic packaging materials, rail transit, aerospace products, cables and electrical wires.

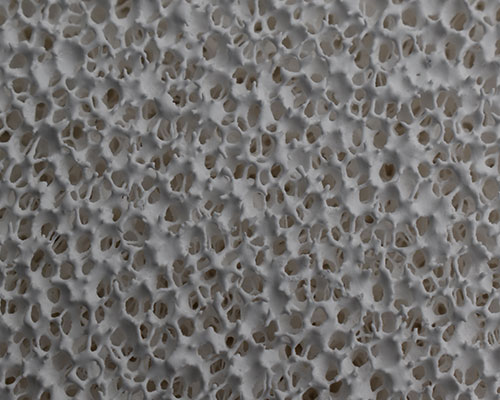

AdTech alumina ceramic foam filter plate uses a three-dimensional network structure and connected pores as a carrier to invade the thixotropic alumina material slurry. The four-square correction center distance automatic extrusion process is used to make the slurry evenly spread. The foam skeleton with the carrier is baked and cured at a high temperature of 1180°C. It is installed in the filter box for the filtration of impurities in the aluminum alloy liquid to meet the production of aluminum alloy precision casting with high added value and high technical performance.