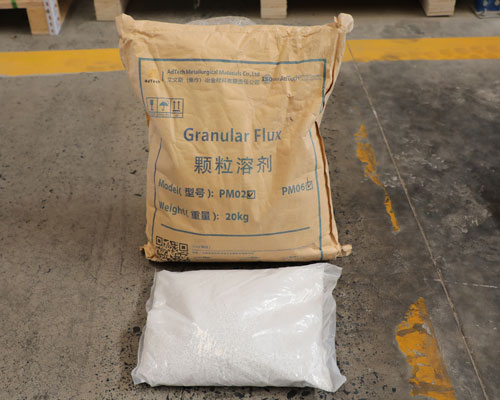

AdTech aluminum granular flux is used for the degassing and slag removal of molten aluminum, which solves the problem of burning caused by chemical reaction and environmental pollution caused by smoke when the traditional flux is put into molten aluminum. The dosage is small and the effect is excellent. It is the best choice for degassing and slagging of aluminum alloy casting.

AdTech has two types of granular fluxes: sodium-free type and alkali-removing type, which meet all the requirements of molten aluminum degassing and slagging.

Aluminum Granular Flux Advantages

- Less usage and cost saving. Our granular aluminum consumption is 0.5-1.0kg, which greatly reduces the consumption and saves costs.

- The degassing and slag removal effect is excellent, and it has the effect of removing alkali metals, which effectively improves the quality of aluminum alloy. The granular flux is a compound after remelting anhydrous granular chloride salt, which effectively removes alkali metal and non-metallic inclusions.

- It achieves the effect of degassing and slag removal through melting, effectively reducing burning loss. Our granular fluxes have undergone physical and chemical reactions during production, and achieve the purpose of removing alkali metal and non-metallic inclusions by melting during refining.

- Environmentally friendly flux with very little smoke during the refining process. This product achieves the purpose of degassing and slag removal through melting, so it does not produce smoke, zero emission of fluoride, and does not pollute the environment. It fully meets the emission standards established by environmentally harmful gas pollution and is an environmentally friendly flux.

- The temperature rises quickly, the aluminum ash is loose, and the aluminum ash is easily recovered. Our granular flux aluminum ash is loose and easy to recover, which is convenient for secondary recovery and saves costs.

The refining effect of the aluminum melt has an important impact on the formation of pores, shrinkage cavities and inclusions, and directly affects the physical and mechanical properties of aluminum alloy castings. Even if subsequent processing and advanced defects occur, there is no high-quality molten aluminum.

Flux purification treatment of molten aluminum is one of the measures to ensure the quality of aluminum alloy products, and it is also the main method to improve the overall quality of aluminum alloy. The granular flux refining effect of molten aluminum has an important and direct influence on the formation of pores, shrinkage cavities, and inclusions.