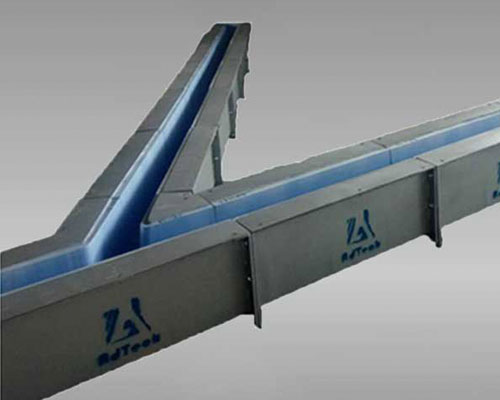

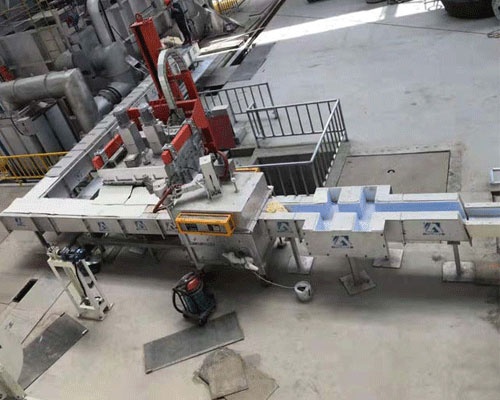

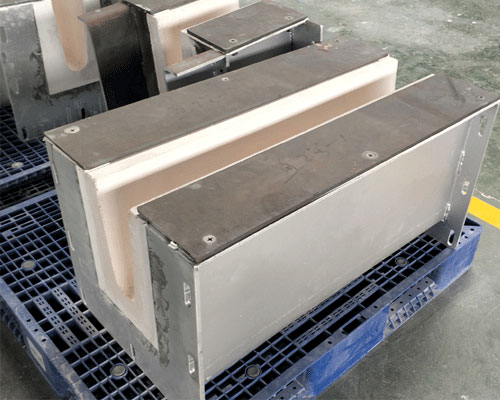

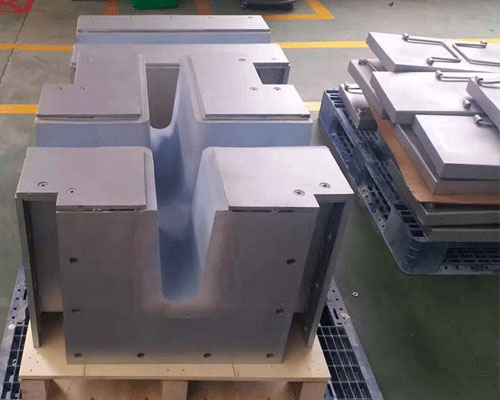

The casting launder has an ultra-long life liner, it uses a new high-silicon molten material molding technology. Heated launders are self-preheating, aluminum transportation troughs. AdTech troughs can transport molten aluminum while reducing or eliminating temperature loss. The aluminum transportation troughs have strong corrosion resistance, non-stick aluminum, and no pollution to aluminum liquid. Production technology of aluminum products that can meet the requirements of high added value and high technical performance. AdTech launder is installed between the furnace and the casting machine. And molten aluminum launder has dual functions: conveying and thermal insulation. The ceramic launder adopts a wet vacuum forming process. The strength is higher than fiber blankets and vacuum-forming felts, and it is suitable for high-temperature fields.

Aluminum Launder Parameter

| Item | Length of Lining | Length of Launder | Insulation cover | Special Dimensions |

| Standard | 500-2000mm | 500-2000mm | 200-500mm | As Drawings |

| Item | Density (g. cm3) |

Rupture modulus (816℃ Mpa) |

>Thermal Expansivity (680℃ K-1) |

Thermal conductivity (540℃W/k.m) |

Operating temperature (MAX) (℃ ) |

| Index | 1.8-2.0 | 18.8-19.8 | 1.56*10-6 | 0.8-0.95 | 1340 |

Product Advantages

- Good insulation performance, reasonable design, and long service life.

- The integral flow grooves adopt noble molten material and have high dimensional accuracy.

- The launder lining has high strength, erosion resistance, heat shock, and sa smooth surface.

- The launder lining has strong corrosion resistance to alloys, increasing special alloys’ service life.

- The temperature drop of the metal liquid is within 2 ° C per meter.

AdTech Trough

AdTech offers trough refractory products that serve various purposes. The trough products include: continuous casting launders, distribution launders, transfer troughs, and small casting troughs. In addition, there are various material options, customizable designs, and coatings available for each trough refractory. Refractory Troughs are one of AdTech Refractories’ primary product offerings. There are several shapes and sizes. Our high-quality launders have been provided to both aluminum industry customers and non-ferrous markets. We have experience producing a large variety of shapes for our customers in different industries. We can often provide insight into the causes of premature launder failures and offer material or design change recommendations to correct the problems. We have provided customers with refractory launder lines, as well as designed and built entirely new custom launder systems.

Instructions for Casting Launder

- Install the flow slot according to the structure of the drawing. Ensure that the overall flow channel is clean, free from damage, and seamless.

- Preheat the installed runners evenly, and heat up at a constant rate for 6-8 hours. So as to remove the adsorbed crystal water, and approach the casting temperature for safe.

- If the ceramic launder of the cabinet does not have the electric heating baking conditions, it must be baked by flame. The key is to control the temperature of the flame, and the second is to avoid direct grilling of the flame. It needs to prevent the liner, tube, and plate from bursting due to thermal stress caused by local heating. The flame is divided into weak flame (red soft flame), medium flame (yellow), and strong flame (blue and white).