Ceramic Foam Filter Seller focuses on the research and development, production and sales of high-absorption ceramic foam filter plates (CFF) used in aluminum alloy casting.

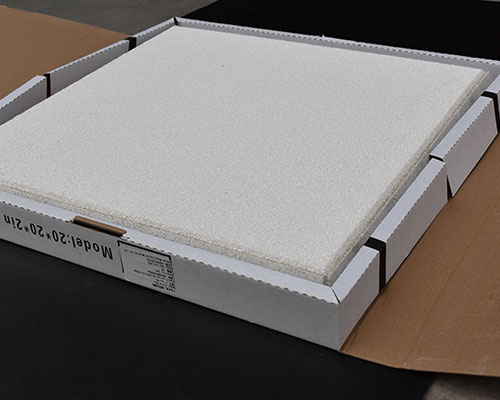

The foam ceramic filter plate uses a three-dimensional network structure and an organic foam with connected pores as a carrier to invade the thixotropic special quality molten material slurry. The four-square correction center distance automatic extrusion process is used to make the slurry evenly spread. On the foam skeleton of the carrier, it is baked and cured at a high temperature of 1680°C.

Ceramic Foam Filter is used in the production of aluminum alloys, aluminum foils, aluminum profiles, etc., it can effectively remove large inclusions in the aluminum liquid, and adsorb micro-sized particles of fine inclusions, purify the hydrogen content in the aluminum liquid, and reduce the oxidation inclusions adsorbed by hydrogen atoms. To improve the surface quality, improve product performance, change the role of the microstructure, and increase the yield. The aluminum melt is filtered and purified.

The yield rate of extruded aluminum profiles for construction in aluminum plants has been low for a long time, and is unstable, and the die life is not high.

After years of production practice and follow-up observation, it was found that the quality of the ingots during the casting process was not high, which affected the product quality.

Inclusions in the ingot destroy the continuity of the metal and are often one of the reasons for the cracks, thereby reducing the processing performance of the aluminum alloy.

The traditional purification process of aluminum alloy is to use flux to remove slag and gas from the aluminum melt, because it cannot remove the fine and suspended non-metallic inclusions in the aluminum melt.

Ceramic Foam Filter Seller email is sales@alalloycasting.com.

When the ceramic filter plate filters molten aluminum, the molten aluminum flows through the tortuous holes of the ceramic filter plate, and the non-metallic impurities and oxide film (commonly known as slag) in the molten aluminum are affected by the axial pressure, friction, and surface adsorption of the molten aluminum. The combined effect of the slag is retained in the inner surface of the hole and the crevice cavity of the ceramic filter plate, thereby separating the slag and the molten aluminum.

After a period of filtering, the slag remaining on the ceramic filter plate also participates in the adsorption of the slag, which can play a filtering role.

Since the performance of the slag adsorbed on the ceramic filter plate is exactly the same as that of the slag to be adsorbed in the molten aluminum, the surface area ratio is much larger than that of the ceramic filter plate, and the surface activity is also much greater than that of the ceramic filter plate.

Therefore, the ability to adsorb and trap the slag in the molten aluminum is far greater than that of the Ceramic Foam Filters For Casting. Because of this, the ceramic filter plate can filter out the fine slag that is many times smaller than its own hole.