CFF filtering system can not only effectively eliminate the large oxidized inclusions in the aluminum liquid, but also filter out the fine inclusions of a few microns that cannot be removed by the traditional process. Because the hydrogen atoms, sodium, potassium and other harmful ions in the aluminum liquid are often adsorbed on the inclusions, the inclusions can become the core of the formation of bubbles, so while filtering the inclusions, these harmful elements in the aluminum liquid can also be reduced.

A refractory alumina ceramic foam filter is placed in the CFF filtering system. Alumina ceramic foam filters are mainly used for aluminum and alloy filtration in foundries and foundries. In order to manufacture high-quality wheels, it is important that the production is free of any external or internal defects. Casting defects are related to mechanical properties and surface quality. The CFF filter system is also used in the production of low-pressure die-cast light alloy aluminum alloy wheels.

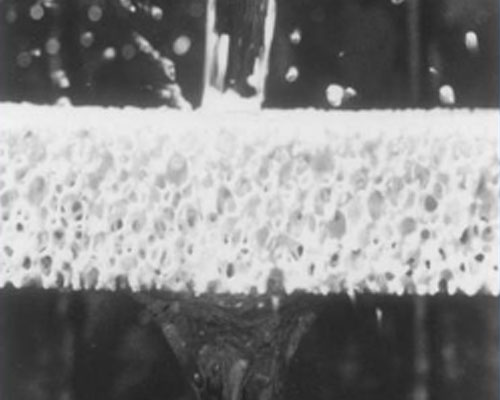

Therefore, the purity of the metal is very important. The purity of defects caused by melting is called inclusions. Inclusions depend on the chemical composition of the melt. Filters are used to separate inclusions from the melt. When the molten metal flows through the CFF filtering system, the filter will contain inclusions.

The ceramic foam filter plate filters out many small inclusions, thereby reducing the required effective crystal nucleus for the solidification of molten aluminum, thereby promoting the growth of molten aluminum nucleation under relatively large supercooling conditions, which can be refined and structured.

The ceramic filter has been running for a period of time, because the internal communication of the filter element may be thickened by the particulate impurities in the fluid medium, and the surface filter cake layer will be thickened, resulting in an increase in filtration resistance. When the flow rate is reduced, it can flow back through the gas and wash with a single liquid mixture. The method can be regenerated, and the equipment is basically restored to its original state. Therefore, timing back-flushing and back-washing can greatly extend the service life of the porous ceramic filter element.