The heater must be preheated according to the heating curve time when the CFF System is used for the first time, shut down for a long time and before filling with molten metal. The purpose is to eliminate any trace moisture in the filter box and avoid solidification of liquid aluminum.

Preheat the CFF System. When the filter is still hot, once the ceramic foam filter is replaced, it should still be preheated. The purpose is that the pre heating of the filter must be uniform and sufficient to ensure full metal filling. There are two kinds of filter preheating procedures, depending on the heating measures of the box. One is to use the preheated gas burner to preheat, and the other is to use the heating cover to preheat.

The condition before filling is that the temperature of the CFF filter box reaches 750 ℃, all necessary devices (metal recovery box, baffle, etc.) are in place. The operators must be familiar with the operation and wear appropriate thermal protection equipment.

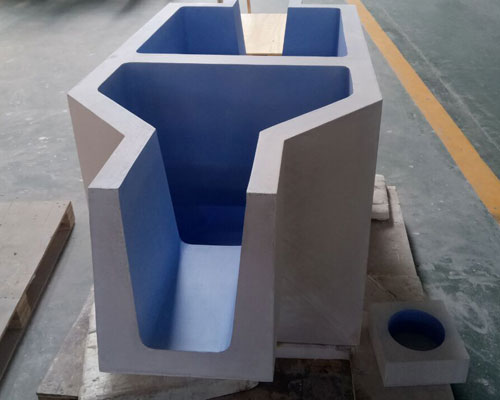

Ceramic foam filter is a chip filter installed on line between metal processing system and casting equipment. It has dual functions of filtering and heating molten aluminum. The principle of filtration is that molten aluminum can capture impurities in molten aluminum through two ceramic filter plates. The effect of filtration depends on the number of holes in the filter medium, and the flow rate depends on the size, number and number of holes of the filter plate.

Because of its convenience, good filtration efficiency and low price, the ceramic foam filter is widely used all over the world. In developed countries, 50% of the aluminum alloy melts are filtered by foam ceramic filter plates, and the foam ceramic filter plate is generally 50m thick, long and wide 200-600mm, and the porosity is as high as 80%-90%. It does not need a very high pressure head when it is filtered. After initial 100150m, it only needs 210m to filter well, and the price is low. However, the foam ceramic filter plate is crisp and easy to damage, and the general situation is only used once. If it is to be used twice or more, melt insulation measures must be adopted, but it is generally not allowed to use more than seven times.