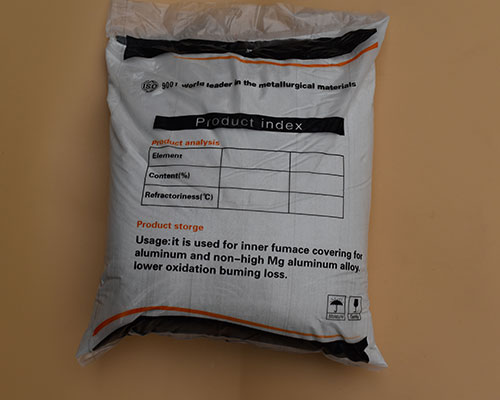

Covering Flux is used to prevent aluminum from being oxidized inside the furnace, thereby reducing oxidation and combustion losses.

We have 2 types, sodium type 550CF and sodium-free type 580CF.

Sodium-free type is specially used for magnesium-aluminum alloy and strontium modified aluminum alloy.

Sodium-containing type, used for furnace covering of aluminum and non-high-magnesium aluminum alloys, to prevent oxidation and oxygen absorption on the surface of the melt, and reduce oxidation burnout. Sodium-free type, used for furnace cladding of high-magnesium aluminum alloy and strontium modified aluminum alloy to prevent oxidation and oxygen absorption on the surface of the melt, and greatly reduce the metal loss caused by the oxidation of the liquid surface.

AdTech covering flux is a white powdery fine particle composed of chloride salt, fluoride salt and other compounds. It can be sprayed with gas in a refining tank, or it can be sprayed directly on the surface of the molten metal for uniform stirring to enter the impurity separation effect. It is used to cover the furnace of aluminum and non-high magnesium aluminum alloy strontium modified aluminum alloy, which greatly reduces the metal loss caused by the oxidation of the liquid surface, reduces the oxidation burn loss, and forms a physical barrier between the molten aluminum and the oxidation gas in the furnace. It can reduce the formation of oxidized inclusions in molten aluminum, produce isolation effect, and help improve casting quality. It can produce aluminum alloy precision castings with high added value and high technical performance for aviation and transportation.

AdTech deslagging flux is a white powder with fine particles, the main components are chlorine salt and fluorine salt, and other compounds. It is environmentally friendly and economical, and meets the requirements for the production of high-value-added, high-tech aluminum alloy precision castings for aviation and transportation. We have two specifications of 622DF and 633DF.

AdTech deslagging flux can reduce smoke and reduce its burning loss, the effect is significant, and the amount of molten aluminum that is brought out when slagging is greatly reduced.

Pingback:Solid Flux for Molten Aluminum Refining – 站点标题

Pingback:Fluxes for Aluminum Melting – 站点标题