Foam ceramic filter technology came out in the late 1970s. The foam ceramic filtration technology has shown great vitality. It has been widely used in semi-continuous casting and shaped castings in the United States, Japan, Canada, the United Kingdom, France, and Switzerland. The foam ceramic filtration technology is regarded as a major breakthrough in the aluminum industry. The filtering function of ceramic foam filter is widely used in the most aluminum foundry.

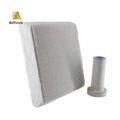

AdTech has been developing aluminum liquid purification equipment since 2012. The degassing unit and CFF filtration equipment have been recognized and used by domestic and foreign customers, especially in the use of industries such as aerospace, aviation, electronics, and computers.

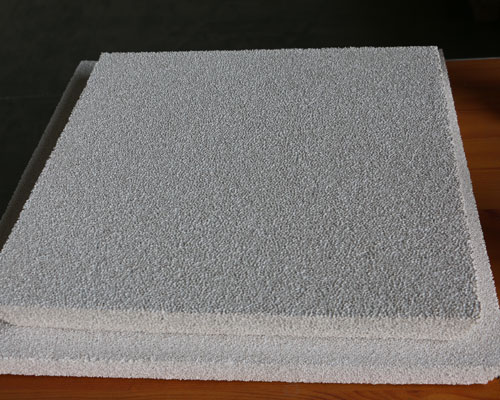

Filtering Function of Ceramic Foam Filter

In the process of aluminum alloy de-smelting, non-metallic inclusions are generated due to the unclean charge and the influence of the external environment. At the same time, in the casting process, due to metal turbulence, drop and splash caused by the large area of liquid metal in contact with air, the oxide film formed by the liquid is also involved in the aluminum liquid. The inclusions in the molten aluminum destroy the continuity of the metal. So it reduces the processing performance and serviceability of the aluminum alloy and affecting the casting quality.

Therefore, while cleaning the furnace charge and refining the liquid metal, it is necessary to further remove the secondary slag inside the melt and the flow process, and filter again.

For the same level of flow system, because the surface film of aluminum liquid in the flow cell and the flow plate is continuous. So the placement of the ceramic foam filter does not need to be very close to the crystallizer.

The filter plate immersed in the aluminum melt is tightly plugged with silicate cotton around it. And the aluminum liquid can only pass through the zigzag holes of the ceramic foam filter. Due to the combined effect of the axial pressure of the liquid flow, friction, surface adsorption and chemical force. The inclusions carried in the aluminum water are firmly retained in the pores of the ceramic foam filter. The surface and the gap in the cave are separated from the metal liquid phase.

The effect of aluminum slag depends on the pore size and thickness of the ceramic foam filter, and the speed of the aluminum melt through the filter. The thicker the ceramic foam filter, the smaller the pore size, and the longer the aluminum liquid flows through the ceramic foam filter, the greater the chance of collision. And the greater the chance of inclusions being retained, deposited, and adsorbed on the pore wall.

It should be noted that when the velocity of the filtrate flowing through the ceramic foam filter is too low, it is not easy to be adsorbed and flow smoothly through the filter pores. When the rate of change is too high, the liquid metal flow will wash away the solid inclusions from the wall of the hole and may take it away. The optimal flow rate is determined by production practice.