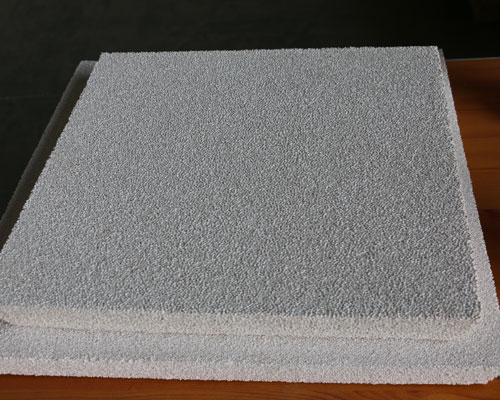

The filtration methods of aluminum alloy melt through a filter made of neutral or active material to separate solid inclusions suspended in the melt is called filtration. the filtration methods of aluminum alloy melt can be divided into two categories: surface filtration and deep filtration. According to the According to the filtration properties,filter material, they can be divided into three categories: mesh material filtration (such as glass cloth, metal mesh), bulk material filtration (such as loose particle packed bed, ceramic filter, foam ceramic filter) and liquid layer filtration (such as flux filtration, flux refining). At present, ceramic foam filter filtration and corundum ceramic tube filtration are the most widely used in China.

Surface filtration refers to the filtration in which solid impurities are mainly deposited on the surface of filter media, also known as filter cake filtration. Mesh material filtration belongs to surface filtration. Deep filtration is also called internal filtration. Solid impurities are mainly deposited in the channel of the filter medium. With the progress of filtration, the effective filtration cross section of the channel gradually decreases, the permeability decreases, and the filtration accuracy improves. Ceramic foam filter filtration belongs to deep filtration.

The filtration mechanism of mesh material filter is mainly to separate the coarse non-metallic inclusions in melt by fence action. It can only trap inclusions larger than the mesh size in the melt. The filtration mechanism of foam ceramic material filter made of neutral materials is mainly to separate solid inclusions from melt by deposition, hydrodynamic and direct interception.

The mass material filter has a large specific surface area, and the melt and the filter medium have a full contact. When the melt carries solid impurities along the long and thin channels with variable cross-section in the filter, the density and velocity of the solid inclusions are different from those of the melt, so it is possible to deposit under the action of gravity; Due to the non spherical nature of the solid particles and the effect of the non-uniform shear force field, the solid particles move laterally and are caught, stuck or absorbed by the channel wall.

The above phenomenon is strengthened by the formation of low-pressure vortex area where the cross-section of the channel changes suddenly. In addition to the above-mentioned filtration mechanism, the bulk material filter made of active materials also produces physicochemical deep filtration due to the effect of surface force and chemical force, so that the melt can be purified more precisely.

The porous ceramic material filter can catch the solid inclusion which is much smaller than its own channel diameter. Liquid layer filter is to wash liquid metal with liquid flux. Its filtration mechanism is based on the physical and chemical reaction between flux and non-metallic inclusions, as well as the wetting, adsorption and dissolution of inclusions by flux.