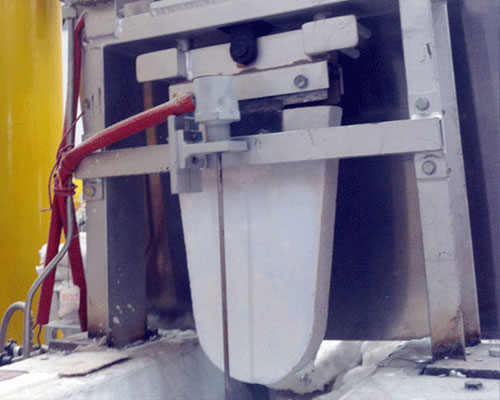

The Refractory Dam is realized by the following technical solutions: including runner baffle, rear guard plate, front guard plate, sealing groove, fixing hole, mounting hole, sealing strip runner, sealing strip holder, cylinder, cylinder bracket, The steel plate at the end of the cylinder and the channel steel on the bottom plate, the runner baffle section is a trapezoidal refractory flat plate, and its shape is consistent with the cross-section inside the runner.

In the production of aluminum alloy slab casting, molten aluminum flows out from the aluminum outlet of the furnace, passes through the long launder to the distribution launder to complete the casting. The launder baffle is used to control the casting. In the beginning, the position of the launder aluminum liquid reaches the position required by the casting technical parameters. Only when the liquid level reaches this height can the molten aluminum quickly pass through the launder and ensure that the temperature of the molten aluminum meets the casting temperature requirements. In this way, the molten aluminum can quickly fill the mold to complete the casting.

The flow trough refractory dam of the original equipment has a trapezoidal cross-section. In production practice, due to the high assembly position of the baffle, when the aluminum liquid reaches a certain height in the flow trough, when the cylinder lifts the baffle up, the momentum of the molten aluminum The resulting shear force causes the baffle to break at the joint and the service life is extremely short. At the same time, the runner baffle is not designed with a sealing groove, and a flat belt is used for sealing, which is not only difficult to fix and high in cost, but also has poor sealing effect and is prone to aluminum leakage. There are still certain safety hazards when the operator handles the damage of the baffle. Due to the damage of the baffle, the slag may fall into the molten aluminum, resulting in quality defects of casting products or waste products.

Aiming at the deficiencies in the prior art, AdTech provides a launder dam, which is used in the production of aluminum alloy slabs to control the position of the launder aluminum liquid at the beginning of the casting.