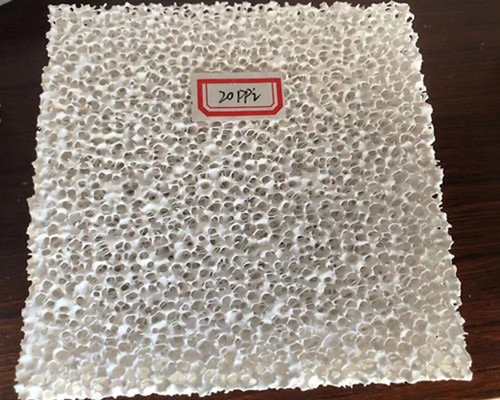

The size ranges of typical commercial CFFs are 10 to 80 ppi. 20PPI -40PPI Ceramic Foam Filters are the most commonly used, for industrial cast houses to reach both the desired casting rate and achieve minimally acceptable filtration efficiency. The 10 to 20 ppi filters have poor particle retention, and are often used for filtration of entrapped bulk, surface borne oxides and other large particulates generated during melting, holding and transport. High pore density filters with 60-80 ppi are only useful for quality sensitive applications, such as surface critical extrusion and sheet products.

Using a 20ppi ceramic foam filter to filter and purify the A356 alloy, by observing the changes in the tensile properties and elongation of the alloy before and after purification, the following conclusions can be drawn:

(1) The filtration and purification of the 20ppi ceramic foam filters can improve the tensile strength and elongation of A356 alloy to a certain extent.

(2) The 20ppi ceramic foam filters can effectively remove the coarse inclusions in the alloy and make the inclusions dispersed in the alloy structure.

(3) The 20ppi ceramic foam filter has larger pores, which also increases the contact area between the melt and the air when purifying the melt, and the oxidation is intensified. When the melt flows, foreign inclusions may be introduced from the filter system, so after the aluminum alloy is filtered and purified, the performance of some samples decreases.

(4) In the range of 720 to 730 ℃, the mechanical properties of the alloy are not sensitive to the pouring temperature. In the range of 700 to 710 ℃, the decrease in temperature is sufficient to cause a substantial decrease in performance.

The 20ppi ceramic foam filter removes most of the inclusions in the melt, making the overall level of tensile strength closer to stable, and avoiding individual coarse inclusions that sharply reduce the tensile strength. However, most of the smaller inclusions cannot be removed, so the overall level of tensile strength cannot be improved.