During the casting process, the metal burning loss of molten aluminum is inevitable, but the resulting loss of metallic aluminum cannot be ignored. How to reduce the burning loss of molten metal becomes the key. It is necessary to strictly control the temperature of the molten aluminum, reduce the disturbance of the molten aluminum by improving the mixing method of the molten aluminum, organize production in a reasonable and compact manner, shorten the contact time of the molten aluminum with air, strengthen the maintenance of the casting equipment, maintain the operating conditions of the equipment, and realize the molten aluminum in the casting process. The undercurrent movement of the aluminum alloy will have a significant effect on effectively reducing the metal burning loss of the molten aluminum during the casting process.

How to Reduce the Metal Burning Loss?

Strictly control and promptly process the temperature of the raw aluminum liquid to meet the needs of casting production. After the molten aluminum with a higher temperature is injected into the mixing furnace, the cold material is added in time to reduce the temperature of the molten aluminum to 730 ℃, which can effectively reduce the influence of temperature on oxidation burnout.

Strengthen the management of refining agents, master alloys, and other charge materials, prevent impurities from being mixed into the charge materials, ensure the cleanliness of the charge materials, and reduce the generation of metal and non-metal oxides during the smelting process.

Improve the stirring method of molten aluminum. In the implementation of the “closed-door stirring” operation, the amount of disturbance of the molten aluminum is much smaller than that of mechanical stirring, which reduces the contact between the molten aluminum and the air during stirring. It can not only reduce the oxidation reaction between air and molten aluminum, but also reduce the inhalation of hydrogen by the molten aluminum, and keep the solubility of hydrogen in the molten aluminum to a minimum. It is not only conducive to the improvement of product quality, but also can effectively reduce the burning loss of molten aluminum.

Use DC launders as much as possible, reduce unnecessary bends, and make the length of the working line of the runners as short as possible. Cover the flow cell with aluminum silicate fiber board.

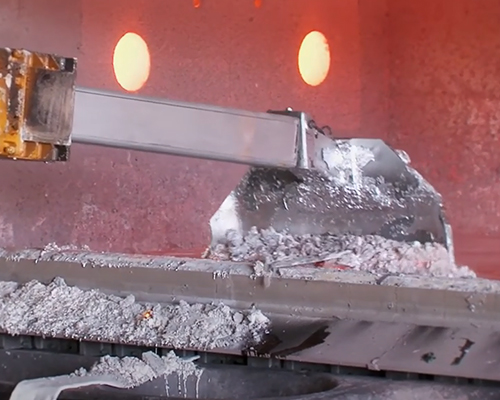

Timely recovery and sorting of waste products, splashed aluminum and residual aluminum in the slagging oxide slag produced during the production process, and adding them to the mixing furnace in an appropriate way for re-smelting is also a way to reduce the metal burning loss.