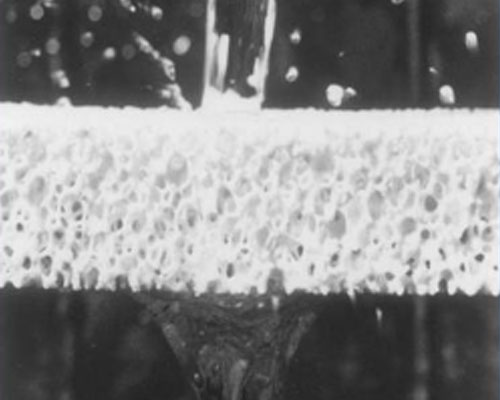

The molten metal filtration process is very important. It is the last step before casting and determines the quality of the casting. In order for the metal melt to pass through the filter plate, the surface tension of the oxide film on the surface of the melt must be overcome, and there must be enough metal indenter to infuse the filter plate.

Fill the CFF filter box at an appropriate flow rate without a large vortex, which can reduce the generation and inclusion of inclusions. Excessive inclusions can greatly reduce the ability of the filter plate to capture inclusions.

Let the ceramic foam filter plate infuse in a natural state, do not beat, shake and interfere with the filter box. Any disturbance will result in local perfusion, which will reduce the filtering effect and the ability to trap inclusions.

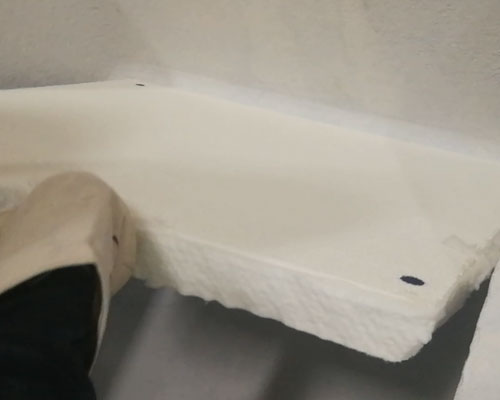

A launder baffle is set on the flow trough between the CFF filter box and the casting machine, and the molten metal is first poured into the filter plate and then filled with the flow trough in front of the launder dam, and then the baffle dam is opened to start casting. This method exposes the filter plate to the full pressure head again, thus ensuring 100% perfusion of the filter plate, and also provides a rapid flow of hot metal that is conducive to the beginning of casting.

Normal Molten Metal Filtration Process

(1) Do not beat the slag in the filter box and launder. The slag will destroy the oxide film on the surface of the melt and cause them to be wrapped away by the melt. The slag on the surface of the melt is harmless, and the slag under the surface of the melt is harmful.

(2) Fill the launder with metal. During the casting process, excessive fluctuation of the metal level in the launder will increase the slag content of the melt. The turbulence should be restricted below the metal surface, and the oxide film on the surface should be protected from being destroyed. Both sides of the filter plate should also be immersed in the melt.

(3) Do not vibrate the filter plate in any way. Vibrating the filter box and launder, scraping the filter plate under the melt, etc., will produce non-metallic inclusions. It may also cause the filter plate to drop slag, and the dropped slag will enter the ingot and remain in the product.