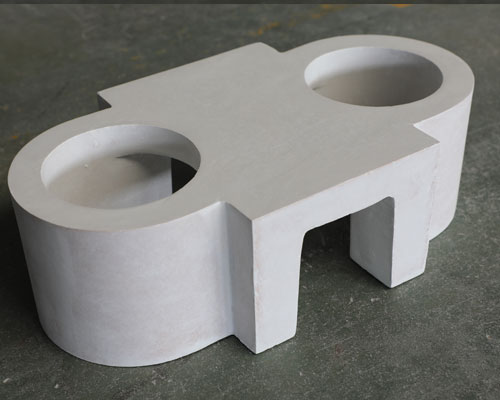

The ceramic distribution plate is an intermediate transfer tool that guides the aluminum melt from the static furnace to the crystallizer. Ceramic distribution plate is also called distributing launder, shunt plate, distribution trough. The distribution launder has great surface quality, great thermal shock resistance, high durability, erosion resistance, and possess nonwetting properties. The distribution troughs are sized to hold a large volume of metal, keeping the erosion on the refractory walls and bottom minimal.

In order to ensure the transfer quality, the following requirements are put forward on the ceramic distribution plate:

- It can make the melt flow smoothly under the coverage of oxide film.

- The metal flow rate to each crystallizer is uniform and the speed is stable.

- Good insulation performance.

- It does not cause re-contamination to the melt and is easy to clean.

- Does not cause a gap in exposure.

- The geometric size meets the process requirements, and the bottom of each flow hole supplying the mold is flat and kept at the same level.

- Lightweight and durable, easy to carry.

There are many structures of the ceramic distributing launder, which vary with the shape, specification, number of castings per casting, and the arrangement form of the ingot. When designing the shunt plate for hot top casting, it is necessary to consider both symmetry and the consistency of the aluminum melt transportation route, otherwise, the melt temperature difference will be too large.

AdTech ceramic distribution plate is widely used for molten metal transfer in the aluminum billet casting process. It adopts vacuum casting, flexible mold forming, smooth and delicate surface, erosion resistance, and heat insulation, has excellent performance and high-cost performance.

AdTech has devoted to research and development of hot-top casting series products used to hot-top casting since 2012, such as: casting thimble, distributing launder, transition plate, hat plate, graphite ring, distribution launder, and other products. These products always use cooperatively for precision molten aluminum casting. Especially match with wagstaff air slip casting unit.