The high-aluminum ceramic insulation molten aluminum conveying trough produced by AdTech is widely used in the aluminum casting industry. It has good corrosion resistance, high temperature resistance, good insulation performance, and long service life.

Aluminum and aluminum alloys are widely used metal materials in modern industry. The current aluminum smelting process is usually: first refine and melt the aluminum block into a liquid state, then cast it into an aluminum ingot and cool it, and then melt the aluminum ingot and cast it in a mold, In this way, various forms of aluminum products can be obtained.

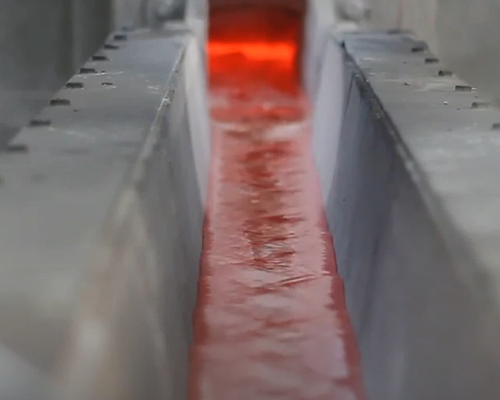

In the aluminum smelting process, the high-alumina ceramic heat preservation launder has the dual functions of conveying and heat preservation. It has strong corrosion resistance, non-stick aluminum, and non-pollution to molten aluminum. It meets the production technology know-how of aluminum products with high added value and high technical performance requirements.

The source of the aluminum block can be electrolytic aluminum that has completed electrolysis, or it can be pressed from various scrap aluminum raw materials. This smelting method first consumes a large amount of energy to melt the aluminum block and make it into an aluminum ingot, and then consumes a large amount of energy again to melt the aluminum ingot before manufacturing aluminum products. The repeated operation not only prolongs the working time and reduces the production efficiency, but also Energy is also a waste and worsens the working environment.

The melting and die casting of aluminum casting is integrated, including molten aluminum. When melting aluminum, the aluminum block is heated in an oven to melt into a liquid state, including heat preservation. During heat preservation, the molten aluminum is transported from the oven to the holding furnace through the conveying trough.

The aluminum alloy melt conveying launder has an excellent high-temperature resistant lining, and it is in direct contact with the melt. It has excellent heat preservation performance, thermal shock resistance, compressive strength, long-term erosion resistance of molten aluminum, and long service life. The AdTech ceramic launder reduces the secondary pollution problem of the aluminum melt in the conveying link of the guide groove to a minimum.