Degassing flux is usually used to reduce the hydrogen content of the molten aluminum alloy. Reducing the hydrogen content will definitely improve the mechanical properties of the resulting aluminum alloy.

When the degassing flux is used in the aluminum melt, a large number of bubbles are generated or reacted. At the contact surface of the bubble and the metal, there is a partial pressure difference between the inside of the bubble and the hydrogen in the metal at the beginning. Due to the partial pressure difference, the hydrogen in the melt penetrates into the bubble. When the bubble rises to the metal surface, the hydrogen is taken into the atmosphere to achieve degassing. Related impurities are also brought to the surface of the melt to achieve melt purification.

The effect of degassing technology on the quality of aluminum alloy includes not only controlling the hydrogen content, but also the final quality of the melt and its cleanliness. The bubble volume increases as the melt wettability becomes worse. Increasing the gas flow rate or reducing the nozzle diameter effectively reduces the bubble volume. Of course, reducing the bubble volume can improve the degassing effect.

During the melting of aluminum alloy, the particles suspended in the melt can be effectively reduced by flotation or precipitation. Most of the oxide inclusions are heavier than the base melt, so they tend to fall into the bottom of the crucible. In addition, the inclusions can also be removed by filtration, which significantly increases the density of the pouring castings.

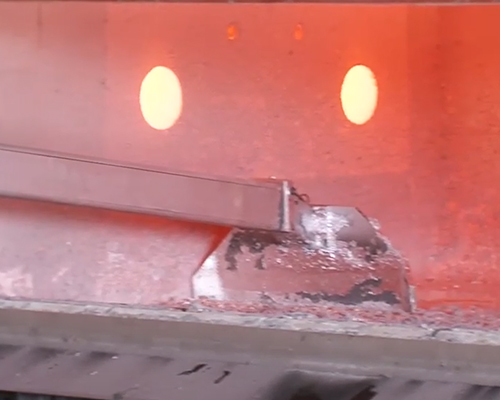

A covering flux is commonly used to prevent an aluminum melt from reacting with the surrounding atmosphere or from re-oxidizing. In this study, melts were degassed with and without a covering flux using a porous bar diffuser. After degassing and holding, the melts were then poured to obtain chilled samples, reduced pressure samples, and permanent mold castings.