The ceramic foam filter for aluminum ingot casting can effectively remove harmful impurities such as inclusions and gases in the metal, and improve the intrinsic quality of the metal. Aluminum foundries use ceramic foam filters to produce aluminum ingots with satisfactory results. In addition, the application of ceramic foam filters in precision castings, aluminum foils and aluminum rods has also achieved preliminary results.

After using ceramic foam filter in the pouring system, the resistance of the metal liquid flow increases, and the liquid metal is in a full state, thus exerting the slag blocking function of the pouring system. When the molten metal passes through the ceramic foam filter, on the one hand, the slag with low density floats up, and on the other hand, the vortex flow is effectively reduced or eliminated.

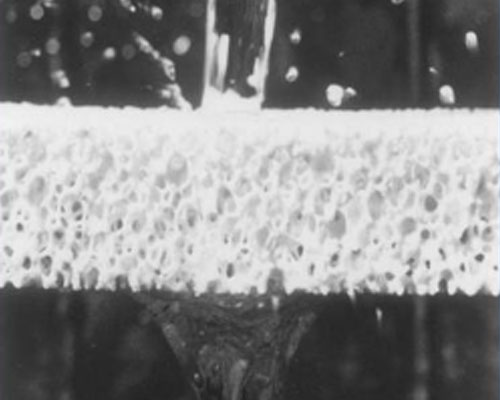

The foundry ceramic foam filter is a tortuous channel, which can effectively block slag mechanically. Many inclusions larger than the filter hole are trapped at the inlet end of the filter. As the number of trapped inclusions increases, a “filter cake” composed of large inclusions is formed on the surface of the inlet end of the filter. The “filter cake” makes the liquid flow thinner, so that inclusions smaller than the mesh size of the filter are also partially captured on the “filter cake”.

When the aluminum liquid reaches the surface of the inlet end of the filter, the phenomenon of adsorption between the liquid flow and the foam grid occurs. At the same time, the “impact” phenomenon of the liquid flow will occur. The filter itself has a flow-blocking effect, and some impurity points are under a certain pressure, because the inclusions and the solid foam ceramic grid have a similar “coherent correspondence” relationship, which is easy to lubricate and cause adsorption. This kind of adsorption is mainly based on non-selective multi-molecular layer physical adsorption, and the inclusions adhere layer by layer on the filter frame until it is blocked.

The ceramic foam filter can effectively intercept the inclusions in the liquid metal and improve the quality of the aluminum ingot.