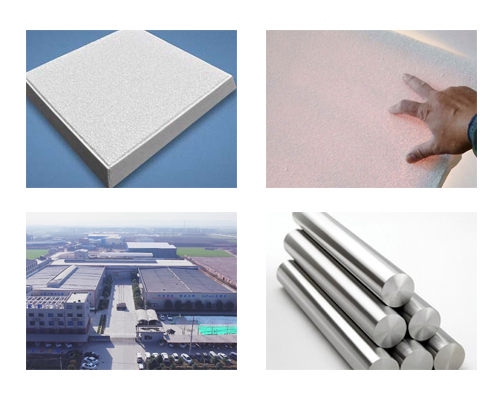

Al2O3 ceramic foam filter is designed for metal casting. Thanks to the mechanism of creating the “filter cake” on the inlet filter side and thanks to the filtration in depth inside the ceramic matrix, these ceramic foam filters are an effective instrument to achieve the metallurgical purity of the molten metal. during the casting process. The filters also calm the filling of the mold, thus preventing the creation of unwanted defects in the casting.

The characteristics of the Al2O3 ceramic foam filter are conditioned by the open 3D structure of the ceramic matrix created by the system of interconnected cells. They are characterized by very good thermal conductivity, stability, and resistance to sudden changes in temperature.

Alumina ceramic foam filters are mainly used in the production of aluminum and aluminum alloy purification process. With more and more and better aluminum product requirements, the application of alumina ceramic foam filters will be more extensive.

Features of Al2O3 ceramic foam filter:

Effectively remove inclusions and reduce scrap rate.

Improve surface quality and product performance.

Improve the microstructure.

In general, choosing an alumina ceramic foam filter should take into account the quality requirements of the finished product, the flow capacity of the molten aluminum tank, the total filtration amount of the molten aluminum, and the cleanliness of aluminum fluids and other factors.

1. Clean the filter housing.

2. Carefully place the filter into the filter housing and press the gasket around the filter to prevent molten aluminum from flowing sideways.

3. Preheat even the filter box and filter plates, closer to the temperature of the molten aluminum.

4. Observe the change of aluminum liquid hydraulic head, the normal initial pressure head is 75-150mm. When the alumina liquid started to pass, the pressure head will be reduced to 25mm below, then the pressure head will gradually increase.

5. After filtration, timely remove the filter plate, clean the filter housing.

Alumina foam ceramic filter molten metal filtration is mainly for the filtration of aluminum and alloys in foundries and cast houses.

With the excellent attack and corrosion resistance of molten aluminum, the filter can effectively remove inclusions, reduce trapped gases and provide laminar flow, so the filtered metal is significantly cleaner. Cleaner metal results in better quality castings, less scrap and fewer embedding defects, which contributes to the bottom line.