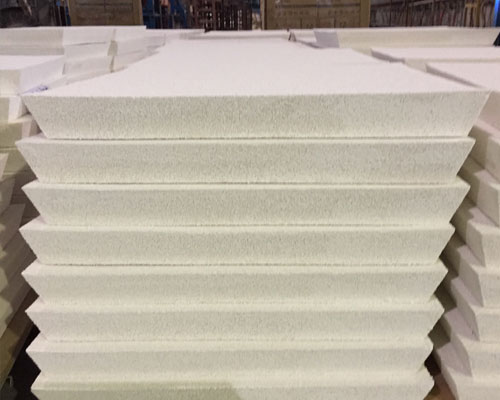

The ceramic foam filter has been used to remove impurities in aluminum fluids for over 30 years. After successful use in industrial practice, it quickly replaced the glass filter, microporous ceramic tube, alumina ball, and other filter elements.

The ceramic foam filter has a mesh hole structure and has a certain strength, can withstand the pressure drop of the metal liquid level and the impact of metal flow, but is fragile and brittle because the material is of precise structure and quality. , and has a large surface area, so the filtering effect is excellent.

After the ceramic foam filter plate purifies the aluminum liquid, it brings great benefits to tape foil and its products (such as cans, sequins for cars, polystyrene printing plates, etc.) regarding aluminum alloy profile manufacturers. several obvious advantages:

1. Increasing the productivity of extrusion.

When using the filter plate to clean the 6063 extrusion billet, we tracked a specific mold and found that the extrusion speed increased by about 20%, and the productivity increased by almost 15%.

2. Increase the service life of the mold and reduce the number of mold repairs.

3. Decrease the pressure.

When the filter plate was used to purify the alloy 6063 melt, the extrusion force was found to be more than 3% lower than unfiltered.

4. The surface quality of the aluminum profile has been significantly improved.

The ceramic foam filter plate for the purification of molten aluminum has tremendous advantages in terms of reducing production costs and improving product quality.

In addition, the ceramic filter plate is used to purify liquid aluminum, and the device is a conventional steel shell lined with a prefabricated refractory brick mat. It is formed horizontally in the metal flow cell, that is, between the flow hole and the casting well. Thus, there is no need to make major changes to the existing casting system, only a small space is needed. What’s more, the filter plate can effectively filter all the metal of one melt, and it is very convenient to take out or replace it after the end of use. It is also suitable for horizontal or vertical casting systems.