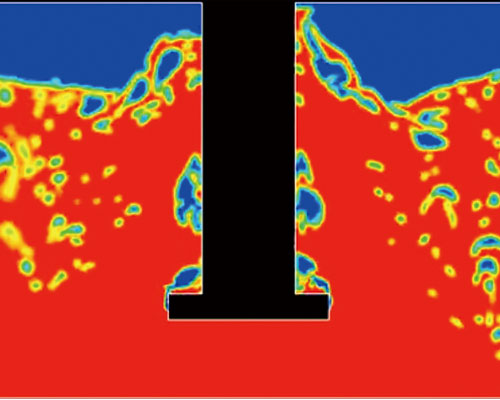

Effectively removing inclusions is one of the main tasks of the aluminum smelting process. Inclusions aggregate and grow, and rely on buoyancy to float up and adhere to the inner wall of the metallurgical container, or be captured and carried away by floating bubbles, which is the main way to remove them. By blowing gas (mostly N2) into the molten aluminum, the flow state of the molten aluminum can be changed, which is conducive to the homogenization of the temperature and composition of the molten aluminum, and the small bubbles generated can capture the inclusion particles and drive the inclusions to float up. It is conducive to the production of pure aluminum.

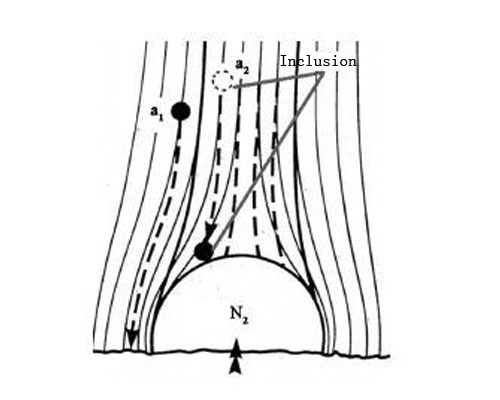

In molten aluminum, in addition to being removed by bubbles by adhesion, inclusions may also be removed by the bubble wake. When the bubble floats in the molten aluminum, the liquid at its tail will fill the bubble to detach and rise, and the resulting volume gap forms a swirling zone at the bubble’s tail. The fluid in this swirling zone forms a wake of the bubble. If the inclusions are located in or near the whirling zone, the inclusions may be drawn into the whirling zone and float up together with the bubbles.

Studies have shown that the shape of bubbles in molten aluminum has a great relationship with its size. Bubbles with a diameter of less than 3mm are spherical, bubbles with a diameter of 3-10mm are ellipsoidal, and bubbles with a diameter of more than 10mm are crown-shaped with a diameter of 1.5mm bubbles will have obvious wakes.

The process of removing inclusions by bubble wake can be broken down into the following three processes:

(1) The inclusions approach the bubble wake area;

(2) Inclusions enter the bubble wake area;

(3) Inclusions circulate in the bubble wake area and float up with the bubbles.

Whether the inclusion particles can be captured by the bubble wake depends on the mutual position of the inclusion and the bubble, the turbulence of the fluid, the size and shape of the bubble and the inclusion, and the surface tension.

Bubble adhesion to remove inclusions and bubble wake to remove inclusions are the main way for bubbles to float up to remove inclusions in the metallurgical process.

The difference in the mechanism of action of the two removal methods should lie in:

(1) The positions of inclusions and bubbles are different before they act. The manifestations of bubble adhesion and removal of inclusions and bubble wake removal of inclusions are that the inclusions act on the bubbles from above and from below.

(2) When the size of the bubble is different, the way the bubble floats to remove the inclusions is also different. In the range of smaller air volume, the inclusions with smaller bubble size are mainly removed by the adhesion and removal of a large number of dispersed small bubbles; in the range of larger air volume, the inclusions are mainly removed by the wake of large bubbles.

In the actual process, the flow of molten aluminum in the metallurgical container is very complicated, and the bubbles will not remove the inclusions in a specific way.