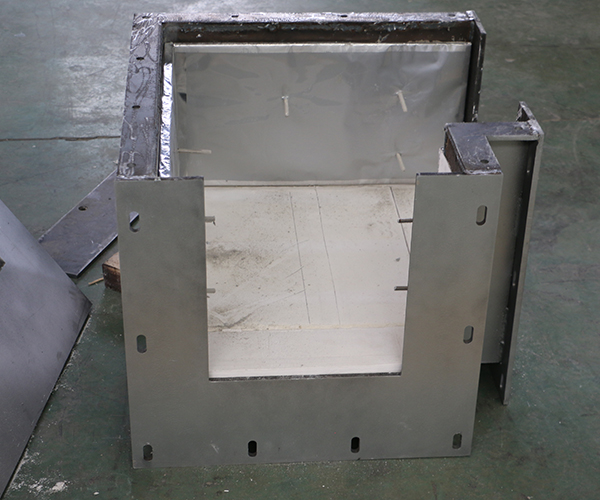

Foundry launder is an important equipment for conveying molten metal. The lower part includes a metal shell with a refractory lining, and the covering part is used to keep the metal in a molten state. The channel through which molten metal flows from the first end to the second end under the action of gravity.

The aluminum is guided and metered from the furnace through launders and troughs to the casting machine. The launders with steel sleeves are lined with refractory materials. They are open launders or launders with lids. The launder is installed at a suitable inclination to influence the flow of the melt by gravity.

In order to transfer and meter the melt, the melt is poured from the furnace into the stabilization launder, which needs to stabilize the movement of the molten metal in it. In addition, an intermediate launder and a metering trough are also required. When the capacity of the casting equipment is increased, the melt launder must become longer, causing the cooling and solidification of aluminum in the launder to become a greater problem. When aluminum solidifies in the launder, the melt flow of the melt is prevented. In order to prevent solidification, the molten aluminum is heated to a sufficiently high temperature in the melting reactor so that the temperature of the molten metal keeps the metal running, and the launder is heated up to the casting machine.

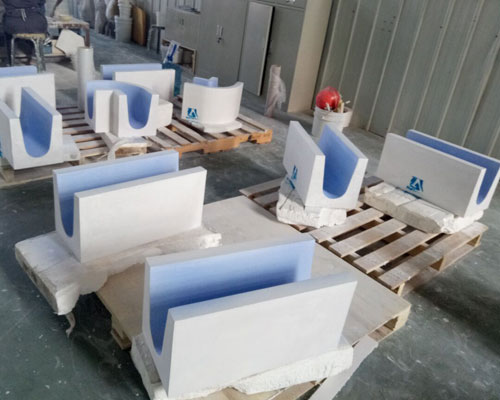

The lining of foundry launder is made of refractory materials, and its wear is proportional to the temperature of the conveyed metal. The higher the melt temperature, the faster the launder lining wears. Naturally, this will bring additional maintenance costs.

At the end of casting, the launder and trough are rapidly cooled, thereby solidifying the molten metal in them. Similarly, for any process disturbances, the flow of molten metal in the trough and launder may be interrupted or reduced to the point where the metal solidifies, and the entire launder system should be repaired before continuing casting or starting a new casting.