Molten Aluminum Filter Aluminium Bangladesh is very important to the quality of Molten Aluminum melt, which greatly affects the post-processing performance and quality of final products. Therefore, all countries in the world are very fond of aluminum melt purification.

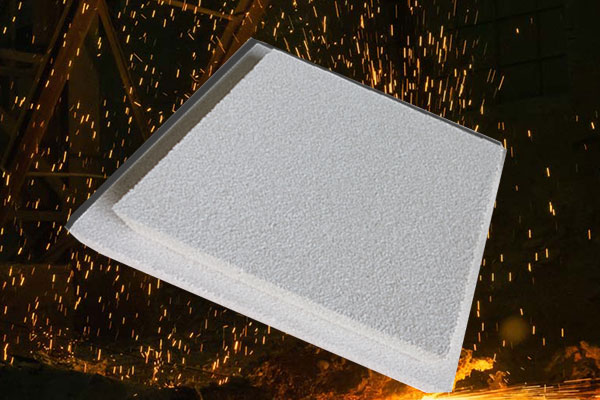

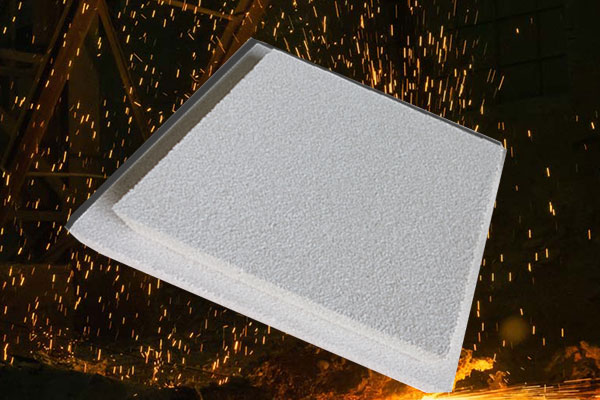

Features of Molten Aluminum Filter Aluminium Bangladesh

1, ceramic filter plate can effectively remove large liquid aluminum inclusions.

2. ceramic filter plate can remove the conventional process aluminum liquid reactive power of a few micron size of small inclusions. At the same time, due to the reduction of the number of effective liquid aluminum crystal nucleus, the liquid aluminum swelling and nucleation under freezing condition, shorten the solidification time, the microstructure is refined.

3. reduce the hydrogen content in liquid aluminum. Hydrogen can be adsorbed on some oxide inclusions, and mixed oxide nuclei can grow into bubbles and inclusions, so its removal gas can also be filtered.

The selection of ceramic foam filter is firstly determined according to the quality requirements of the final casting product based on the content of impurities in the aluminum melt and the flow rate of melt transfer.

High impurity content, casting quality is normal. The foam ceramic filter with large mesh can be selected, and the glass fiber cloth coarse filter can be added before the foam ceramic filter. At this point, it is important to use glass fiber cloth for coarse filtration in semi-continuous casting.

There are many reasons for aluminum pollution

On the one hand, in the melting process, aluminum in a molten or semi-molten state exposed to the furnace atmosphere, easy to oxidize, react with water vapor, easy to absorb hydrogen. Also easy to produce metal slag (such as lining debris, flow of chloride, carbide, etc.) and coarse intermetallic compound particles.

On the other hand, some of the waste materials in the combined charge carry some non-aluminum impurities during the cycle. Because the waste comes from the process waste and geometric waste of each working procedure in the factory and different waste.

These impurities make the slab produce bubbles and inclusions, which seriously affect the purity of metal melt, and affect the machining performance, mechanical properties, corrosion resistance and appearance quality of the product.

India has one of the most dynamic aluminium markets in the world, with increasing production and consumption every year.

Large infrastructure projects are expected to generate additional growth in aluminum consumption, while India’s power, construction, packaging and transportation sectors also provide significant growth opportunities, which are expected to double over the next decade.

In India, aluminium consumption per capita is 1.3kg, compared to 12kg in China and 25kg in Europe, India has a lot of room to improve.