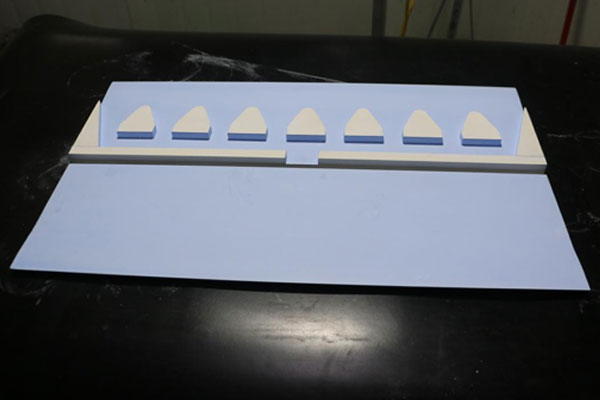

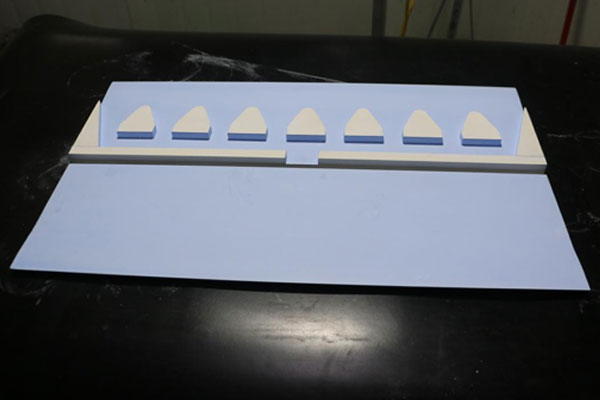

Molten Aluminum Feeding Castertip consists of side rails, shunt blocks, pressure plate fixing bolt holes, melt inlet, bolts or nails, stop bars, nozzle upper platen, nozzle lower platen, ears, melt outlet, nozzle frame and divider blocks are connected together. The dividing block and the dividing block are connected into one body by bolts or iron nails through the fixing bolt holes of the pressure plate. In the middle of the ear is the melt outlet, and the baffles are installed on both sides of the upper platen of the casting nozzle and the lower platen of the casting nozzle. The side rails are fixed on both sides of the upper pressure plate of the casting nozzle with bolts or iron nails and are connected with the lower pressure plate as a whole. The nozzle has the advantages of improving production efficiency, saving energy and reducing consumption.

The Molten Aluminum Feeding Castertip is a key component of an aluminum strip casting and rolling mill, the quality of which directly affects the quality of the strip and the yield of production.

Feeder Castertip can effectively prevent molten aluminum from eroding the gate and avoid carbonization. The fractured tissue is a fine and uniform layered fibrous structure to prevent the existence of flocculent tissue. The working surface coating is uniform and smooth.

The casting nozzle plate is stored in a ventilated and dry environment, and it is strictly protected from moisture, and do not place objects on it. The product is calcined at high temperature, does not contain organic matter, and has zero shrinkage at 800 °C. It can be used in various twin-roll continuous casting and rolling mills. It is a slag-free ball made of ceramic fibers for the production of aluminum sheets and foils. This product has the characteristics of high strength, smooth surface, and wear resistance, and is suitable for casting and rolling of high-speed aluminum sheets.

Molten Aluminum Feeding Castertip Product Advantages

1. It is integrally formed with nanofiber composite materials, processed by high-precision equipment, precise in size control, and suitable in density and stiffness.

2. The key parts are reinforced with nano-coating, the surface of the hole is sealed, no delamination, good non-stick performance, and enhance the corrosion resistance of aluminum liquid.

3. The symmetrical flow channel with reasonable internal structure design meets the hydrodynamic requirements of aluminum liquid.

4. Good thermal insulation, effective constant temperature control of parameters in the casting and rolling area, is the best choice for casting and rolling high-quality aluminum foil billets.

5. The deformation is small, it is easy to adjust the gap between the nozzle and the roller, improve the surface quality of the aluminum foil blank, and effectively improve the white stripes and dark lines.