In the production process of die-casting, in order to improve the service life of the mold cavity and punch, and make the die-casting parts demold smoothly, to ensure that the surface of the die-casting parts is smooth and clean, the outline needs to use some auxiliary materials, such as mold release agent. Boron nitride paint can be used as a high-temperature release agent.

As an inert inorganic high temperature resistant lubricating material, boron nitride coating has excellent high temperature lubricity, chemical inertness, acid, and alkali resistance characteristics. Non-bonding and non-wetting molten metal liquid can completely protect the refractory materials that are in direct contact with molten metal and molten slag.

Boron nitride paint can prolong the service life of the equipment and facilitate the cleaning work after casting. At the same time, the fine particles of the refractory are prevented from entering the aluminum melt, which improves the cleanliness of the product. In general, boron nitride coatings have excellent performance and are a very important raw material. AdTech boron nitride coating is lubricated, thermally conductive and has good insulation.

Application of Boron Nitride Release Agent

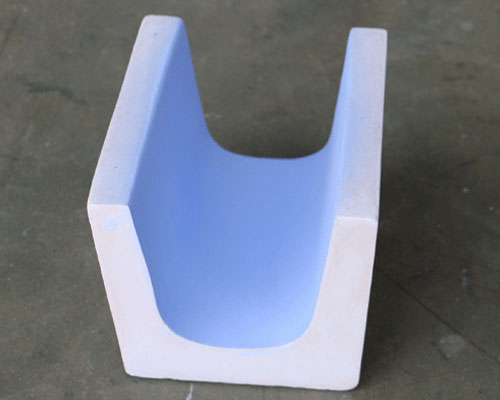

Paint on the surface of casting launder, distribution launder, casting table lining, filter box, alumina ceramic ring, casting tips and nozzle, crucible furnace and other materials. Specially formulated coatings can be used in die-casting molds for aluminum rods.

It is used in various copper casting channels and molds. The boron nitride coating has good non-stick copper properties.

Sintering of metal and ceramic powders is usually carried out on graphite plates. After spraying a layer of boron nitride non-stick paint on the graphite board, it can obviously eliminate the pollution, reaction and adhesion of carbon to the sintered parts.

Boron nitride coating has high temperature lubricating properties, most glass will not stick to boron nitride, it is an ideal material in glass processing. It helps to reduce the time required to clean the mold, make it easier to demold, and improve the service life of the mold/compression mold, while minimizing the surface defects of the glass products.

The application of boron nitride in the injection molding process can improve the demoulding effect and increase the production rate, thereby benefiting plastic box and synthetic rubber injection molding manufacturers.