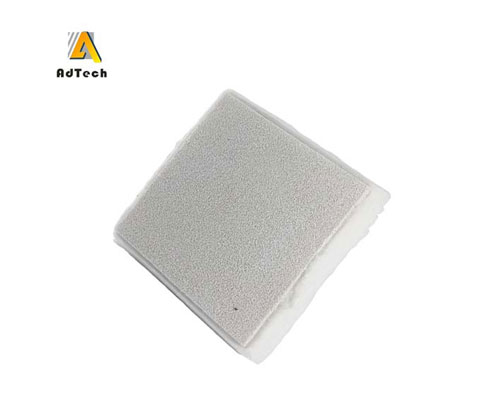

The ceramic filter for molten aluminum has the following filtering benefits:

1) Ceramic filters can filter out the inclusions in the casting, reduce the gas in the casting, reduce the turbulence degree during the metal flow filling, and reduce the surface defects of the casting. The reject rate of castings is reduced significantly. The properties of castings can increase the compression sealing, elongation, and tensile strength of castings, and improve the surface finish of castings. Ceramic Filter for Molten Aluminum also can improve the fluidity of molten metal and increase the filling and feeding capacity of castings.

2) Simplifies the design of gating system. The length of runner is reduced and the casting process is improved. Casting processing reduces processing time and tool damage, improves casting surface quality, and reduces waste products by 60-80%.

Ceramic filter for molten aluminum is the best purification functional component to eliminate casting defects and obtain perfect casting quality. It can be used in the filtration of liquid metals for foundry.

Advantages of Ceramic Filter

1. Ceramic Filter has a very high temperature working strength, thermal shock resistance, and metal flow impact resistance. In the work, there is no slag or cracking phenomenon, which ensures the quality of molten metal filtration.

2. Ceramic Filter has high room temperature strength and mechanical impact resistance.

3. Ceramic Filter has a very significant filtering effect. It is much higher than that of fiber filter. The remarkable filtration effect is related to the filtration mechanism of the velocity criterion.

4. Ceramic Filter can effectively reduce the turbulent flow of molten metal caused by pouring, make the mold filling smooth and avoid casting surface defects.

5. Ceramic Filter has high chemical stability and is not affected by the acidity and alkalinity of liquid metal and does not change the chemical composition of liquid metal.

6. With very high dimensional accuracy, Ceramic Filter can be used in the production line of automatic placement of filter. Ceramic filter is the best filter selected by foundry manufacturers from the aspects of practicability, reliability, quality, and price.