Porous filter material purification mechanism is generally described as diffusion interception and inertial collision interception or through screening, sedimentation and deep bed filtration. AdTech is a Ceramic Foam Filters Supplier, our porous ceramic foam adopts organic foam with a three-dimensional network structure and connected pores as a carrier, and invade it into the thixotropic alumina material slurry. Ceramic foam filter uses automatic extrusion equipment to make the slurry evenly distributed in the foam skeleton.

Porous Purification Mechanism

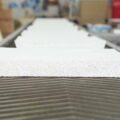

- Through the mechanical filter of inertial interception and diffusion interception, friction and sedimentation, the filter effect is proportional to the aperture of the foam ceramic mesh. The smaller the mesh, the stronger the interception ability of small particles.

- The sediment or filter cake layer effect makes the particles deposit in the melt, and the tortuous grid support wall improves the particle capture ability.

- A rough surface is formed due to the gap of the main body of the grid support, which increases the flow of molten aluminum and ceramic particles at the solid-phase interface. It can make the flow of molten aluminum flow more disorderly, which is beneficial to the capture and deposition of particles.

- Due to the micro-cracks and pinholes on the surface of the online support, a fluoride solvent with a strong affinity for Al2O3 particles is deposited, which promotes a complete filter cake effect and strong chemical adsorption, and enhances the ability to capture particles.

Choose Porous Filter Material

Choose the correct porous filter material to improve the cleanliness of the aluminum melt. According to the content of impurities in the aluminum melt, the flow rate of the melt flow and the quality requirements of the casting, the foam ceramic filter plate is selected.

- The impurity capacity is large, and the quality of the casting is average. You can choose the larger perforation mesh of the foam ceramic filter plate, and add a coarse filter cloth in front of the filter plate. It can intercept large particles of slag to prevent clogging of the filter plate.

- The quality requirements of casting products are very high. Choose small-hole mesh, that is, a new type of foam ceramic board with a large mesh.

- The specification of the filter plate is determined by the flow rate of the melt and the total output. The flow rate is large, the total amount is large, the filter plate hole is small, and the selection specification is large.