Molten aluminum filtration method is mainly to let the aluminum melt pass through the ceramic filter to separate the solid inclusions suspended in the melt. This method mainly removes the inclusions in the melt and has little effect on hydrogen removal. Therefore, in practical application, molten aluminum filtration method is often combined with the blowing method.

Blowing method, also known as bubble floating method, is a purification process of aluminum melt developed in the 1970s, especially has a good effect on hydrogen removal. Inert gas (such as nitrogen, argon, etc.) is introduced into the aluminum melt to form bubbles. Hydrogen in the melt diffuses into these bubbles under the action of partial pressure difference, and is eliminated with the rising of bubbles to achieve the purpose of degassing. In the process of floating, bubbles can also absorb some oxidized inclusions, which can remove impurities.

With the improvement of the requirement of melt purity, the hydrogen removal technology has been improved and developed from the original single pipe injection to the multi hole blowing head and to the current rotary nozzle. Since the 1980s, the method of rotating nozzle blowing has become the main development trend of advanced aluminum purification technology abroad. For example, the online degassing system by Adtech, rotating nozzle inert gas floating method. The equipment is equipped with two graphite gas rotating nozzles. The gas forms small dispersed bubbles through the rotor of the nozzle. At the same time, with the rotor stirring the melt, the bubbles evenly disperse into the whole melt, which increases the contact area between the gas and the liquid, extends the movement distance and residence time of the bubble in the aluminum liquid, increases the gas volume and absorbs the gas in the melt And oxide inclusions float to the surface of the melt, so as to achieve the purification effect of degassing and impurity removal. The hydrogen removal efficiency of this method is about three times that of single pipe injection method.

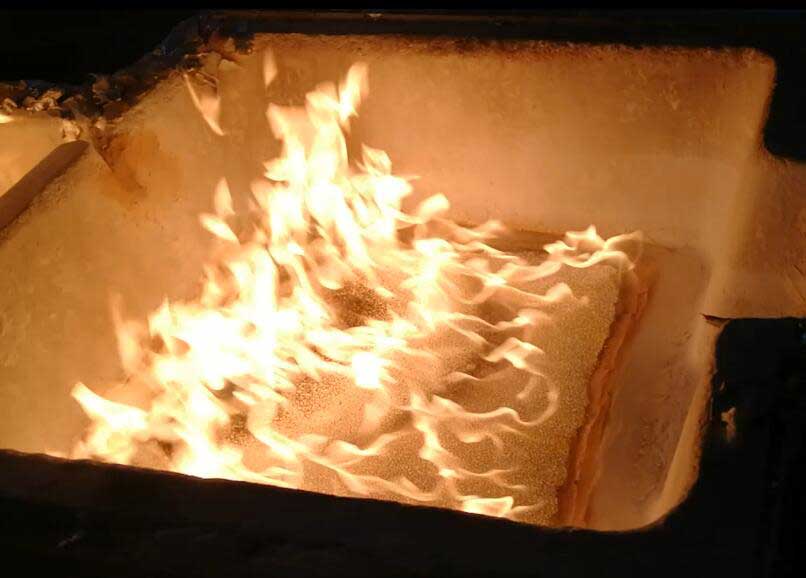

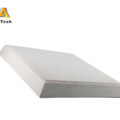

There are many kinds of filtration, and the best ones are corundum filter tube and foam ceramic filter plate. Corundum filter tube has high filtration efficiency, but it is expensive and inconvenient to use. Foam ceramic filter board is a new type of ceramic filter material developed in recent years. Its characteristics are easy to use, good filtration effect, and low price. It is widely used all over the world. The aluminum alloy melt of over 50% of developed countries is filtered by foam ceramic filters. At present, the box type foam ceramic filter technology is widely used. It is a CFF filter box with gas preheating cover system. When the liquid aluminum passes through the filter plate, the inclusions in the melt pass through the mechanical barrier of the filter to eliminate and separate. The filtration precision can be 2 μ m and the filtration efficiency can reach 99%.