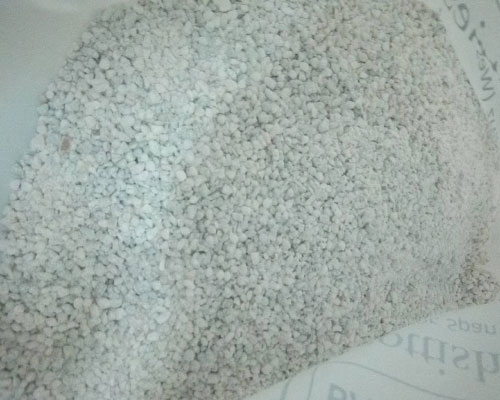

Slag remover is used in metal smelting and casting because it melts at high temperatures above 1200 ℃ and has cohesiveness. Slag Remover is also called Deslagging Flux, Aluminum Drossing Flux. It can effectively collect and absorb scum and slag inclusion on the surface of metal solution. It has stable chemical properties and will not cause secondary pollution to molten metal. The quality of Deslagging Flux is not only related to the production process and quality control, but also depends on the quality of raw materials to a great extent. The performance of slag remover is mainly reflected in the reaction time and cohesion. Good flux is characterized by fast reaction time, good adhesion and no slag drop.

Characteristics of Slag Remover

1. Various slag and impurities can be collected in the casting solution to ensure the cleanliness of molten metal.

2. Simple slag discharge, no dross, no pollution, no damage to ladle wall and furnace wall.

3. Heat preservation to reduce the loss of alloy elements.

4. Reduce harmful elements in molten metal, such as phosphorus and sulfur.

5. Eliminate slag inclusion, improve casting quality and reduce reject rate.

6. Contact with molten metal, stable reaction, no splash, non-toxic and tasteless, no smoke and dust, no impact on human body.

How to Use Aluminum Drossing Flux

When the metal melts in the furnace, a small amount of flux is sprayed onto the surface of the molten metal to remove the slag initially, and then a thin layer is laid on the surface of the molten metal. After the reaction is sufficient, the slag is removed before discharging.

A little Aluminum Drossing Flux is sprayed on the surface of molten metal in the ladle, and then a little covering agent is sprayed after the slag is removed. The addition amount is about 0.1% to 0.3% by weight of liquid metal.

Before casting, the slag remover is spread on the surface of the liquid to form a slag insulation layer. With the decrease of metal content in ladle, the slag remover will decrease.

The slag layer can be poured out after casting to avoid the slag stripping process. At the same time, it can also provide insulation and oxygen isolation for ladle and prevent secondary oxidation.

Before discharging the liquid metal, a little Drossing Flux For Aluminum can be sprayed on the bottom of the ladle. It is suggested that the slag remover should not be placed at the bottom of ladle before the molten aluminum is discharged, so as to avoid affecting the effect of spheroidizing inoculation.