With the continuous expansion of the application of aluminum alloy materials in various fields of national economy, higher and higher requirements are put forward for the internal quality of aluminum alloy materials. In the production process, the chemical composition of aluminum alloy and the defects such as shrinkage cavity, porosity and slag inclusion of ingot must be strictly controlled. Because the internal quality of processed products is affected by the quality of ingots, and the internal quality of ingots largely depends on the quality of melt. Therefore, the cleanliness of aluminum alloy melt is very important. According to the existing equipment and process conditions, the purification technology of aluminum melt is designed for reducing the hydrogen content in aluminum melt, so as to obtain high quality ingot.

Purification Technology of Aluminum

The main gas in aluminum melt is hydrogen (volume fraction is about 60% – 90%), followed by nitrogen, oxygen, carbon monoxide, etc. Aluminum melt purification technology mainly includes bubble floating method, vacuum treatment method, ultrasonic treatment method and rare earth dehydrogenation method. Bubble floating method is widely used because of its simplicity and high efficiency. Hydrogen removal process of aluminum melt by bubble floatation: the hydrogen atoms dissolved in aluminum melt migrate to the periphery of the bubble of purifying agent (argon or nitrogen, etc.), adsorbed around the bubble, and formed into hydrogen molecules to enter the bubble, and finally escaped from the aluminum melt with the bubble floating upward. The dehydrogenation rate equation reflects the dehydrogenation efficiency from the perspective of dehydrogenation kinetics.

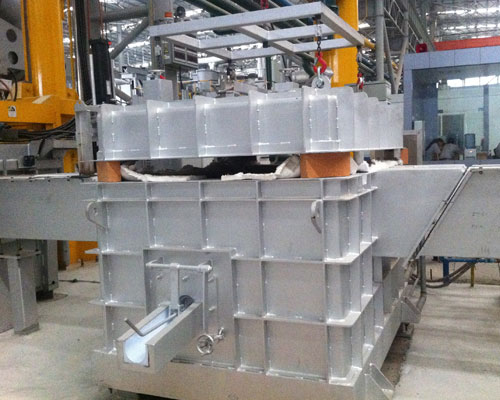

The purpose of using on-line degassing equipment is to further purify the aluminum melt outside the furnace, and better remove the gas and slag in the aluminum melt (the principle is floating slag removal and partial pressure difference bubble degassing). The degassing efficiency of on-line degassing device is related to aluminum liquid capacity, inert gas flow rate, air pressure, bath temperature, rotor speed, effectiveness of rotor impeller and sealing of molten pool. The best degassing efficiency is determined by optimizing the flow rate, rotating speed and pressure.

The secondary pollution of aluminum melt mainly occurs in the aluminum flow channel from the furnace hole to the casting point. On line degassing and filtering devices are installed on the aluminum flow channel, so as to further purify the aluminum melt. In the process of the melt passing through the channel, it will absorb hydrogen in varying degrees when contacting with the moisture in the air. When aluminum melt contacts with water, chemical reaction occurs, atomic hydrogen is absorbed by the surface of aluminum liquid and then diffused into the melt. The whole dissolution process is physical adsorption chemical adsorption diffusion.

In practice, the secondary pollution of aluminum melt should be controlled well from the outlet of degassing unit to the casting point. The effective way to control is to speed up the flow velocity of melt in the flow channel and CFF filter box, reduce the contact area between liquid aluminum and air, and reduce the humidity in the air. For the CFF filtering unit, the filter box with strong sealing should be adopted and the residence time of aluminum melt in the box should be reduced. Especially in the case of low hydrogen content in the melt, the higher the sealing effect is required, otherwise the effect of on-line degassing treatment will be reduced by subsequent secondary pollution, and the ideal aluminum melt can not be obtained.