The online aluminum degassing system achieves better degassing effect with less time and less overall cost.

As these growing markets demand higher quality, higher strength, and higher machinability, high-quality aluminum is often selected as a key casting for aircraft, automotive, and computer industries.

When melting aluminum scrap, the process of removing excess hydrogen is very important to produce high quality aluminum castings.

Hydrogen is introduced by water. Excessive hydrogen will produce porosity and overall shrinkage, which will have a negative impact on the mechanical properties of finished aluminum. It is important to remove excess hydrogen during melting and casting.

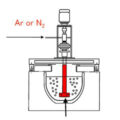

Inert gases, such as argon or nitrogen, may be introduced into the molten metal to remove hydrogen. When the inert bubble moves upward through the molten aluminum, hydrogen diffuses into the inert bubble and disappears. Traditional degassing systems limit mixing, especially at the bottom, which requires higher velocity, which results in greater surface turbulence. The bubble is larger, and it takes longer time for degassing to obtain the desired results. The furnace requires excellent bubble shear and dispersion, longer bubble residence time in the metal, complete molten metal cycle, non clogged rotor, and higher thermal shock resistance. In addition, they want to use less inert gas in the process.

The degassing unit unique rotational motion of the rotor head cuts bubbles to prevent gas from rising. The ingenious rotor pushes the metal outward and pulls it out from the bottom to improve the flow, thus increasing the reaction surface area. It runs at a lower rpm and eliminates the “dead zone” in the melt.

The aluminum degassing system is a powerful tool for removing inclusions, reducing defects, voids and brittle fracture surfaces. While reducing inclusions, the metal also has increased fluidity, higher strength and ductility, improved machinability and better surface finish. All of these advantages reduce tool wear, scrap and rework.