Filtration is a solid-liquid separation process that uses a porous filter medium to intercept solid particles in the suspension and let the liquid pass through. Compared with the gravity sedimentation method, the filtration operation not only has a fast solid-liquid separation speed, but also a more thorough separation, which can obtain a filter cake and a clear liquid with a smaller liquid content. Therefore, filtration is a universal and effective solid-liquid separation method. Generally, the suspension sent for filtration is called filter slurry, the porous medium that traps solid particles is called filter medium, and the sediment layer trapped on the filter medium is called filter cake or filter residue. The clear solution is called the filtrate.

Different filter media can be used according to the nature of the filter slurry and the size of the solid particles. When the filter slurry passes through the filter medium, the solid particles are trapped to form a sediment layer. The filtrate is often turbid at the beginning of the filter and needs to be returned to the filter. After the sediment layer is formed, the filter can be effectively carried out. During the filtration process, the thickness of the filter cake continues to increase, the resistance of the filter cake to the fluid also continues to increase, and the filtration rate continues to decrease. Therefore, the resistance of the filter medium to the fluid is often less than the resistance of the filter cake, and the filtration rate is mainly determined by the thickness of the filter cake and its characteristics (mainly the porosity of the filter cake). The porosity of the filter cake is related to the shape of the solid particles, particle size distribution, particle surface roughness and particle filling methods.

According to the characteristics of filter cake, it can be divided into compressible filter cake and incompressible filter cake. The incompressible filter cake is mainly composed of mineral particles and crystalline precipitates, and the fluid resistance is less affected by the pressure difference on both sides of the filter cake and the particle deposition rate. The compressible filter cake is composed of amorphous sediments, and its fluid resistance increases with the increase in the pressure difference between the two sides of the filter cake and the material deposition rate.

The filter medium is often the support of the filter cake, and the filter cake layer plays a real filtering role. The filter medium should have sufficient mechanical strength, corrosion resistance, good performance, and low resistance to fluid.

There are three types of commonly used filter media:

(1) Granular media include gravel, sand glass slag, charcoal and diatomaceous earth, etc. These media have hard particles and can be stacked into layers to handle suspensions with small solids.

(2) Filter cloth media: Filter cloth can be woven with metal wire and non-metallic wire. Commonly used metal materials include stainless steel, brass, Montessori alloy, etc., and non-metallic materials include wool, cotton, linen, nylon, plastic, glass, etc. . The selection of the filter cloth material should mainly consider factors such as the corrosiveness of the liquid, the working temperature of the solid particles and the wear resistance.

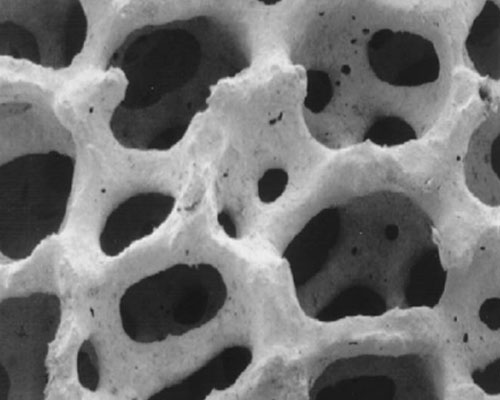

(3) Porous solid media: commonly used are porous ceramics, porous glass, porous metals, porous plastics, etc., often made into a plate or tube. This kind of medium has small pore size, high mechanical strength, resistance to acid, alkali, salt and organic solvent corrosion. It is suitable for filtering materials containing fine particles. The disadvantage is that the micropores are easy to block and need to be regenerated regularly (backflush or chemically) to maintain its filterability.