The purification method of aluminum melt is to separate the solid inclusions suspended in the melt through a filter made of neutral or active materials. According to the filtering properties, the filtering method of aluminum alloy melt can be divided into surface filtration and deep filtration. According to the filter material, it can be divided into mesh material filtration (such as glass cloth, metal mesh), block material filtration (such as loose particle packed bed, ceramic filter, foam ceramic filter) and liquid layer filtration (such as Flux layer filtration, electric flux refining) three categories.

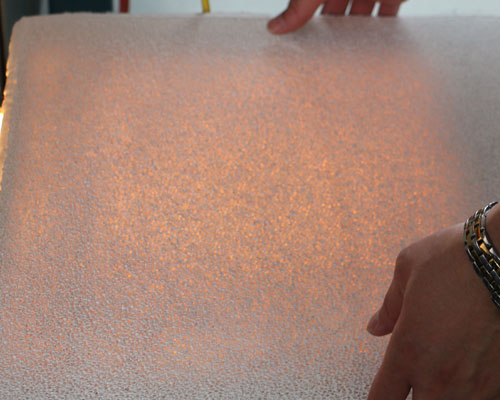

At present, the filtering method of aluminum widely used in aluminum foundries is foam ceramic filter. Although the loose particle packed bed filter is simple, the preparation work is laborious and the alloy replacement is inconvenient.

Surface filtration refers to the filtration of solid impurities mainly deposited on the surface of the filter medium, also known as filter cake filtration. Net-like material filtration belongs to surface filtration. Deep filtration is also called internal filtration. The solid impurities are mainly deposited inside the pores of the filter medium. As the filtration progresses, the effective filtration section of the pores gradually decreases, the permeability decreases, and the filtration accuracy improves.

Bulk material filtration is a deep filter mesh material. The filtering mechanism of the filter is mainly to mechanically separate the macroscopic and coarse non-metallic inclusions in the melt through the action of the fence, which can only trap the inclusions in the melt whose size is larger than the mesh size (assuming that the inclusions cannot be deformed). The filtering mechanism of the block material filter made of neutral materials is mainly to mechanically separate the solid inclusions in the melt through deposition, hydrodynamic and direct interception.

The bulk material filter has a large specific surface, and the melt and the filter medium have a sufficient opportunity to contact. When the melt carries solid impurities along the slender channel of the filter with variable cross-sections, it is caused by solid inclusions. The density and speed of the melt are different, so it is possible to deposit under the action of gravity. Also, due to the non-spherical nature of solid particles and the uneven shear force field, the solid particles move laterally, thereby being hooked, stuck or adsorbed by the channel wall. The above phenomenon is strengthened by the formation of a low-pressure vortex zone where the cross-section of the tunnel changes suddenly. In addition to the above-mentioned filtering mechanism, the block material filter made of active material also produces physical and chemical deep filtration due to the effect of surface force and chemical force, so that the melt can be purified more finely.

The bulk material filter can trap solid inclusions that are much smaller than the diameter of its pores. The liquid layer filter uses liquid flux to wash the liquid metal. Its filtering mechanism is based on the physical and chemical reaction between the flux and the non-metallic inclusions and the wetting, adsorption and dissolution of the flux to the inclusions.