The mouth of the mixing furnace (furnace hole) is equipped with an aluminum liquid flow control device. In order to make the aluminum liquid flow smoothly in the aluminum launder, the launder is usually made into a certain slope. The length and direction of the launder depends on the configuration of the mixing furnace and the aluminum ingot casting unit.

Flow regulator, commonly known as balance (composed of lever, buoy, plunger, flow aluminum hole). There is a flow regulator between the opening of the launder and the boat-shaped ladle, and the flow rate at the outlet of the aluminum launder is automatically controlled by the principle of lever and buoyancy through the detection of the liquid level. So that the flow of molten aluminum into the rotary distributor is stable and uniform, but with the change of the molten aluminum level in the mixing furnace, depending on the operator’s experience and visual observation of the aluminum ingot size in the mold, it is necessary to fine-tune the balance in time.

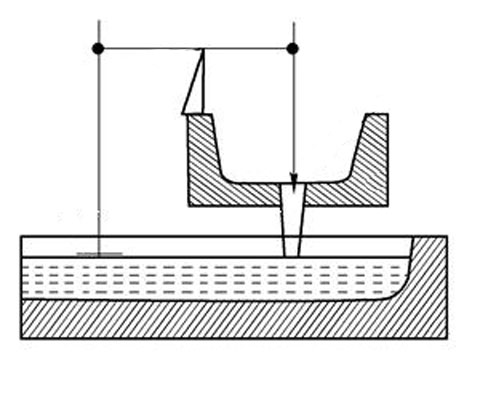

The lever type flow controller is made using the working principle of the lever. One side of the lever is a buoy, which can be moved up and down by the buoyancy of molten aluminum, and the other side is a plug made of graphite or light refractory material. The end of the plug is cone-shaped, just facing the nozzle of the casing. When the aluminum liquid level drops, the buoy descends, and the plug rises or moves forward and backward through the lever, and more liquid aluminum flows into the front box from the nozzle; When the liquid level rises, the buoy is lifted, the plug is gradually lowered, the metal flow through the nozzle is gradually reduced, and the height of the front box is restored to normal.

The liquid level control method of the front box where the flow through and the front box are not on the same level, it is suitable for the flow supply mode where the flow through and the front box flow trough have a drop.

The liquid level control method of the front tank in which the launder and the front tank are on the same level. The principle is to drive the buoy up and down through the lifting of the liquid level of the front box launder, and then the connecting rod acts on the drill plug to achieve a stable supply of molten aluminum.