The alumina ceramic foam filter plate is specially developed for the purification of molten aluminum. The molten aluminum flows through the tortuous and porous three-dimensional foam structure. The tiny impurities are intercepted, adsorbed, deposited, and adhered to the pore walls. The micron-level impurities in the molten aluminum are efficiently filtered out to the internal defects of the aluminum alloy.

Alumina Ceramic Foam Filter Plate Advantages

1. High strength, not easy to drop slag.

2. High opening rate and uniform pore structure.

3. The pore size is the same, and the flow is stable when the molten aluminum passes.

4. A complete range of filter plates ranging from 7 inches to 26 inches and mesh sizes from 20 PPI to 80 PPI.

5. Heating, easy to operate, replace immediately after use, without damaging the lining of the filter box.

6. Fire-resistant cotton and expanded cotton edging can be provided.

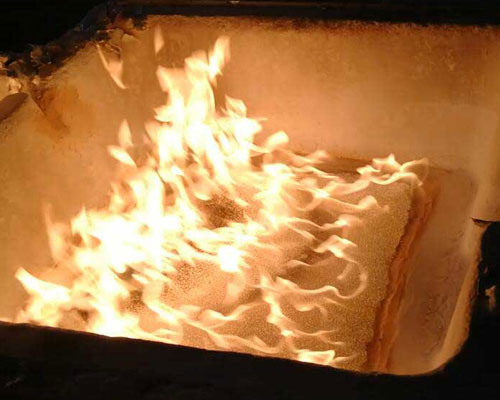

Place the ceramic filter plate in the filter box. Before casting, the ceramic filter plate and filter box should be preheated at about 600°C. Because the ceramic filter plate is hard and brittle, and the thermal conductivity is not good, the initial heating should be slow, first preheat to 200 ℃, and then increase the heating speed, otherwise the ceramic filter plate is easy to chip or break.

Since Dubai Aluminum used our company’s alumina ceramic foam filter plate to filter molten aluminum, the hard impurities such as alumina slag in the ingot have been greatly reduced, the continuity of the metal has been improved, the mechanical properties have been improved, the yield rate of extruded profiles has been steadily improved, and the service life of the mold has also been greatly Strengthening, reducing scratches, bringing them better economic benefits.

During the filtration process, the slag adsorbed on the ceramic filter plate gradually grows up after adsorbing and intercepting the slag in the aluminum liquid. Under the agitation and scouring of the liquid flow, the slag with extremely low strength may be broken or removed from the ceramic filter plate. If the ceramic filter plate is thicker or has small holes during the slag shedding process, it may be intercepted or adsorbed again. Therefore, in general, the thicker the ceramic plate, the smaller the holes, and the slower the flow rate of the molten aluminum through the ceramic plate, the better the filtering effect. The total amount and cleanliness of molten aluminum basically do not affect the filtering effect, only the life of the ceramic filter plate.