As the first process of aluminum processing, if the billet has “innate defects” (such as inclusions, pores, etc.) caused by the casting, no matter what advanced technology or equipment, it cannot be used in a series of subsequent processing processes (such as rolling). Manufacturing, extrusion, heat treatment, surface treatment, etc.) to make up for this congenital defect, and then it is difficult to ensure the quality and performance of aluminum products. Therefore, in order to give full play to the potential of the material and give full play to its own performance, the production and quality control of the cast slab must first be solved. We provide online rotary degassing unit and filtering equipment to solve casting quality problems.

The main source of hydrogen in the aluminum alloy melt is that in the aluminum alloy smelting process, the moisture in the atmosphere and on the surface of the raw material enters the alloy melt through metallurgical reactions, causing the melt to absorb hydrogen. There are two forms of its existence in molten aluminum. About 90% of the hydrogen is dissolved in the melt as interstitial atoms. About 10% of a small part of hydrogen is adsorbed on the surface or gap of the inclusion in the form of bubbles, forming hydrogen bubbles with a negative radius of curvature.

The presence of hydrogen will adversely affect the performance of aluminum alloys. The hydrogen in aluminum and its alloys will cause pores of varying sizes in the casting billet, which will destroy the continuity of the metal material and reduce the effective cross-section of the component. The stress concentration around the pores greatly reduces the processing performance of the cast billet; in the semi-finished product, there will be delamination defects and the second type of hydrogen embrittlement caused by hydrogen, which increases the brittleness of the alloy during forging and rolling. The hydrogen in the supersaturated state and the combined state is an important reason for the secondary porosity and surface blistering of the cast slab during the homogenization process.

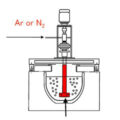

Our online rotary degassing unit basic degassing method is the floatation method, the principle of which is to pass gas or gas-producing substances into the aluminum melt to generate bubbles. According to the principle of partial pressure difference, the hydrogen dissolved in the aluminum melt continuously diffuses into the bubble under the action of the pressure difference. When the bubble rises to the surface, the hydrogen diffused into the bubble enters the atmosphere with the bubble. At the same time, the surface of the bubble can automatically adsorb the inclusions, and the inclusions are discharged to the liquid surface as the bubbles float to form slag.