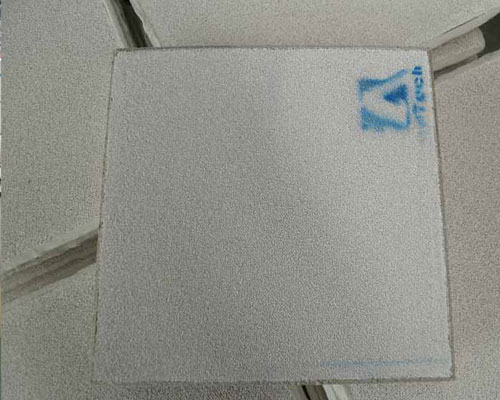

The molten AL ceramic foam filter plate is a new type of filter plate made of industrial sponge as a carrier, filled with heat-resistant ceramics, and then sintered. When the ceramic filter plate filters the molten aluminum, the molten aluminum flows through the tortuous holes of the ceramic filter plate, and the non-metallic impurities and oxide film (commonly known as slag) in the molten aluminum. Due to the combined action of the axial pressure, friction, and surface adsorption of the molten aluminum, it is retained on the inner surface of the ceramic filter plate and the crevice cavity, thereby separating the slag and the molten aluminum.

As automakers adopt more compact designs and reduce car production steps, aluminum forming, die casting, and finishing will only become more challenging.

Cast structural components are becoming larger, flatter, and more complex, with complex shapes and thin walls. They must meet higher mechanical performance requirements and have the required strength and rigidity while reducing thickness.

Cast aluminum and aluminum alloys are aluminum castings produced by casting methods; deformed aluminum and aluminum alloys are processed products produced by pressure processing methods. The quality of aluminum ingot raw materials directly affects the quality and production efficiency of aluminum alloy die-casting. Good raw materials can reduce mold wear, extend mold life, reduce costs, and improve production efficiency.

Since Alcoa has adopted molten AL ceramic foam filter to filter molten aluminum, hard impurities such as alumina slag in the ingot have been greatly reduced, the continuity of the metal has been improved, the mechanical properties have been improved, the yield rate of extruded profiles has been steadily improved, and the service life of the mold has also been greatly enhanced.

Since 2012, AdTech has been focusing on R&D, production and sales of high-absorption ceramic foam filter plates (CFF) used in aluminum alloy casting. AdTech molten Al ceramic foam filter plate technology has been widely accepted by the market and is applied to many series of aluminum alloy products: micron High-precision filtration and purification of cast aluminum alloys such as aluminum foil wool materials, PS board bases for printing, canning materials, elastic packaging materials, rail transit, aerospace products, cables and electrical wires.