High quality foam ceramic filter for molten aluminum plays a very important role in improving casting quality. It can effectively filter liquid and solid non-metallic inclusions in molten metal in one time and two times, thereby reducing slag hole, improving mechanical properties of castings, reducing machining allowance, improving surface finish and prolonging the service life of castings. At present, all kinds of complex castings, such as cylinder blocks and cylinder heads produced by foundry company, all require foam ceramic filter for molten aluminum, with annual consumption reaching tens of millions of pieces. AdTech has a complete set of foam ceramic filter quality control system, including technical standards, testing equipment and testing methods, in order to achieve the control of production quality requirements.

When alloy is made in the mixing furnace and refining agent is added, the slag inclusion and aggregate caused by improper operation are not removed, resulting in secondary slag inclusion.

The refractory brick chips and the bottom sediment are entrained into the molten aluminum.

When the molten aluminum passes through the flow mouth and chute of the smelting furnace, the deposits at the flow mouth and the adhesive mud on the chute flow along the flow of molten aluminum and are brought into the finished aluminum alloy products.

The oxide on the surface of the flowing liquid aluminum is entrained into the liquid aluminum to cause slag inclusion.

After the aluminum alloy material is mixed with slag, the properties of the alloy deep-processing parts are destroyed, and the yield rate is reduced, which will cause certain economic losses. In production, it is required to adopt the means of slag removal and filtration to eliminate slag inclusion as much as possible.

Slag inclusion in aluminum alloy casting is one of the main factors that affect the quality of deep-processing products. The quality of products directly affects its market share and economic benefits. In order to survive and develop, we must improve the added value of products and go deep processing.

In order to remove the slag inclusion in the aluminum alloy, the slag inclusion problem in the aluminum alloy has been greatly improved by adding slag remover and careful operation, but it is not complete. In order to improve the situation thoroughly, the aluminum plant has been experimentation with a foam ceramic filter plate for filtering and purifying aluminum liquid.

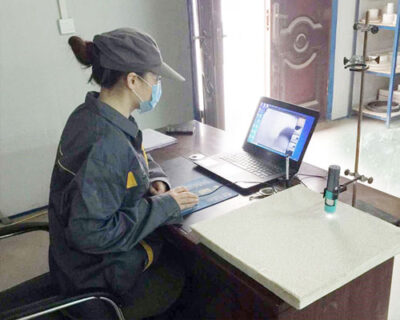

The test results show that the problem of slag inclusion after filtering and purifying by foam ceramic filter plate has been thoroughly solved. Users have good feedback. Due to the large amount of ceramic filter plate and high price, in order to reduce the production cost, we have a special ceramic foam filter plate production line. Before leaving the factory, we ensure the product quality through quality inspection.