Foam ceramic filtration technology came out in the 1970s and has been rapidly widely used in the United States, Canada, Japan, France, Australia, and Switzerland. It is the most effective way to remove inclusions in the aluminum melt.

In recent years, some new technologies for purifying molten aluminum have been researched at home and abroad, such as vacuum dynamic processing, ultrasonic continuous degassing purification and corundum ceramic filters, which have received very good results. However, these process methods are relatively complicated and costly, and it is difficult to be widely promoted in production. As for the metal filter screen and fiber cloth filtration, only large inclusions in the aluminum alloy melt can be removed, but the inclusions below the micron level cannot be removed, and the metal filter screen will also pollute the aluminum alloy. The use of foam ceramic filter plates can filter out fine inclusions and significantly improve the mechanical properties and appearance quality of the castings.

Foam Ceramic Filtration Technology

The ceramic foam filter plate has a multi-layer network and multi-dimensional through holes, and the holes communicate with each other. When filtering, the molten aluminum carries inclusions and flows along the tortuous channels and pores, and is directly intercepted, adsorbed, deposited, etc. when it comes into contact with the foamed framework of the filter plate. When the melt flows in the hole, the channel of the filter plate is curved, the melt flowing through the channel changes the flow direction, and the inclusions collide with the hole wall anvil and firmly adhere to the hole wall.

Ceramic Foam Filter Uses

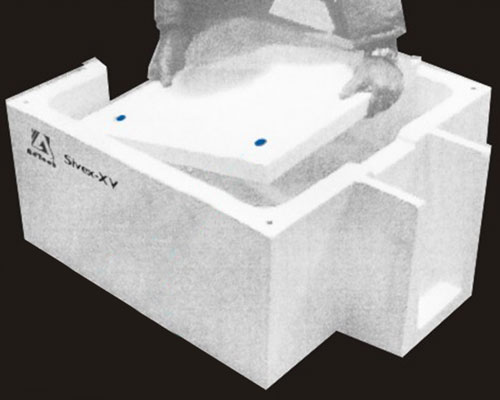

The ceramic foam filter plate is installed in the CFF filter box. It can pass through the lines of chilling and heating without cracking, and has high strength, good heat preservation performance and other advantages. The closer the filter box to the splitter plate, the better, because this can shorten the flow distance after the aluminum liquid is filtered, and reduce or avoid the oxidation produce. The molten aluminum flows out of the furnace mouth, passes through the filter box, and then flows through the flow trough into the distributing plate. When the filter device is started, the drop before and after the melt filtration is about 50mm. With the extension of the filtering time, the inclusions on the surface of the filter plate and the pore wall increase, the filter flow rate decreases, and the front to back difference increases. At the end of casting, the drop increases to 60-120n dishes. The selection of the filter plate must be based on the flow of molten aluminum, and secondly, the cleanliness of the melt, the highest content of inclusions and the total throughput of the melt should be considered.

The ceramic foam filter molten metal filtration effect is mainly guaranteed by its size and porosity. The larger the pores of the filter plate, the worse the slag removal effect. For aluminum castings with strict requirements, a filter plate with small pores should be selected. For example, a filter plate with 40~45 holes/inch is used.

When designing the filter device, it is necessary to ensure that the filter plate is immersed in the molten aluminum during the casting of the melt according to the specifications of the selected pallet, as well as the drop of the furnace mouth and the splitter plate. In addition, it must be considered that the installation and disassembly are very safe and convenient, and the aluminum liquid in the filter box can be completely drained after the melt is cast.

Practice has proved that the foam ceramic filter filtration technology is currently the most effective tool for removing oxidized inclusions in famous melts. General fiber filtration can only remove large inclusions, while foam ceramic filter plates can simultaneously filter out large inclusions and small inclusions.