The production cost of hot-rolled aluminum billet is high, and the aluminum foil needs to be tempered during the production process, which increases production costs. At present, 1235 alloy is commonly used, and the ratio of Fe/Si is generally controlled between 2.5 and 4.0. Double zero aluminum foil development trend: 8079 alloy casting rolling replaces hot rolling significantly.

Double Zero Aluminum Foil Casting Composition Control

The cleanliness of aluminum raw materials should be strictly controlled, especially the ratio of scrap back to the furnace.

Metal addition: master alloy, fluxing metal additive, aluminum metal additive.

Harmful element requirements: Pb+Cd+Cr(VI)+Hg≤100ppm; trace elements meet the following requirements: Li≤5ppm, Na≤10ppm.

Melt purification-degassing: During the smelting process, different degrees of gas, metal and non-metallic inclusions in the melt are the main factors that affect the quality of the final aluminum foil pinholes, holes and broken belts. Hydrogen content control indicators: ①Holding furnace outlet <0.25ml/100gAl, ②Front box ≤0.10ml/100gAl.

Melt purification-slag removal: In the degassing process (the theory of slag gas associated), most of the slag inclusions are removed, and there are still a few micrometers of slag inclusions suspended in the melt, and online filtration is required.

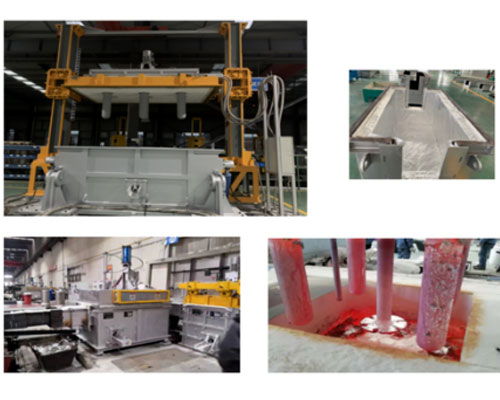

AdTech is a high-precision online degassing filter equipment manufacturer specializing in the development and production of new materials. The degassing efficiency of degassing unit is stable at an average of 60%. The inner lining of the degassing box is made of high-silicon melting material, which has a good effect of non-sticking aluminum and no pollution to the aluminum melt. A baffle plate is designed inside to ensure the stability of the surface of the aluminum melt and prevent the air and oxides on the surface of the aluminum melt from being rolled into the aluminum melt. The sealing structure of the online degassing equipment is designed to fully seal the box cover, the box body, and the aluminum melt inlet and outlet, which effectively prevents the slagging caused by the secondary oxidation of the aluminum melt and effectively improves the degassing effect.

AdTech plate filter equipment has a long-life furnace body and adopts a new type of high-silicon melting manufacturing technology. It is mainly used for high value-added and high-tech performance requirements for melt purification in the production of aluminum products, replacing the high-cost ceramic tube type in the industry Filter equipment and ordinary filter equipment products.