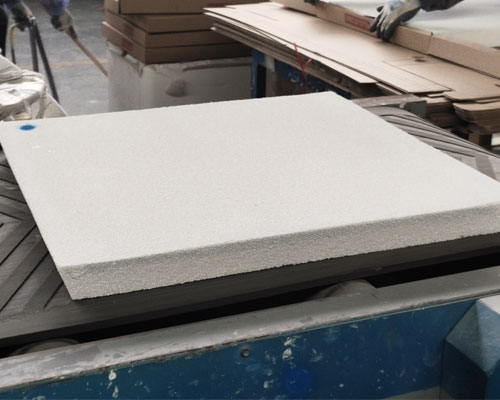

Ceramic foam filter CFF can effectively remove all kinds of micro-scale inclusions in aluminum melt. The molten aluminum becomes a stable laminar flow, which is conducive to filling. Ceramic foam filter has a unique three-dimensional structure, good mechanical strength and chemical stability, and excellent aluminum corrosion resistance. Strictly control the pore size and through-hole rate to obtain a stable filtering effect. There is a sealing ceramic fiber gasket around the ceramic foam filter plate to help seal the ceramic filter plate in the filter box. AdTech alumina ceramic foam filter products are mainly used in the purification process of aluminum and aluminum alloy production. It is also used as various gas-solid and liquid-solid separation media, catalyst carrier, burner, sound absorption and environmental protection.

The quality of the aluminum melt is very important, it greatly affects the subsequent processing performance and the quality of the final product. Therefore, the purification of aluminum melt is an essential step.

There are many reasons for aluminum contamination. On the one hand, during the smelting process, aluminum is exposed to the air in a molten or semi-molten state and is easily oxidized. It easily reacts with water vapor and absorbs hydrogen, and easily forms various non-metallic slags (lining fragments, chlorides, carbides in the slag) and coarse intermetallic particles. On the other hand, the charge will introduce some non-aluminum impurities during the cycle. These impurities usually cause bubbles and inclusions in the slab, thereby seriously affecting the purity of the molten metal. Therefore, they further affect processing performance, mechanical properties, corrosion resistance and product appearance quality.

PPI represents the number of inches per inch of CFF. The higher the ppi value in the filter plate, the more holes per inch and the smaller the holes, the better the filtering effect. If the hole is too small, the aluminum alloy will not pass the fluidity restriction, so you should choose the correct model.

Alumina foam ceramic filter plate is formed by high-temperature sintering, and interconnected openings are formed on its outer surface and inside. When the fluid passes through the microporous channel, suspended matter, colloidal particles and macromolecular organic matter are captured on the surface of the product, and the fluid passes through the microporous channel to produce various physical and chemical effects for purification and filtration.

Ceramic foam filter CFF has excellent thermal shock resistance, strength, high porosity and specific surface area. It can filter and absorb as few inclusions as possible in molten metal. It has a unique rectifying effect, which can prevent laminar flow from flowing smoothly and quickly, and prevent air bubbles from entering. It is suitable for different requirements of refractoriness and casting speed in the foundry industry. Alumina ceramic foam filter plate can significantly improve the quality of castings and promote cutting, reduce tool wear and reduce manufacturing costs.