Deslagging flux is also known as a slagging agent. It is a mixture that separates liquid metal and oxide. The deslagging flux has the function of removing slag in the high-temperature molten metal. AdTech slagging agent uses a unique technology, which can improve the traditional impurity separation effect in the molten metal. It is used in the casting and rolling process of aluminum alloy products. The slagging agent can fully recover valuable and effective metals, improve the direct yield of the product, reduce the cost, and reduce the slag rate. Deslagging Flux is especially suitable for the cleaning and slag removal of die-cast pure aluminum and aluminum alloy. Because the temperature of the metal is only above the melting point during heat preservation, especially in the crucible furnace, the upper mouth is open and the surface temperature is very low. The flux is particularly suitable for occasions that require heating and cleaning at lower temperatures.

Features of Deslagging Flux

- AdTech slagging agent adopts the principle of metal liquid compound combination. It can reduce the smoke and burning loss, and is environmentally friendly and economical.

- AdTech slagging agent has a moderate melting point, good fluidity, and a small amount of metal liquid per ton.

- AdTech slag removing agent has a significant effect of separating aluminum and slag. It greatly reduces the amount of aluminum liquid brought out during slag removal.

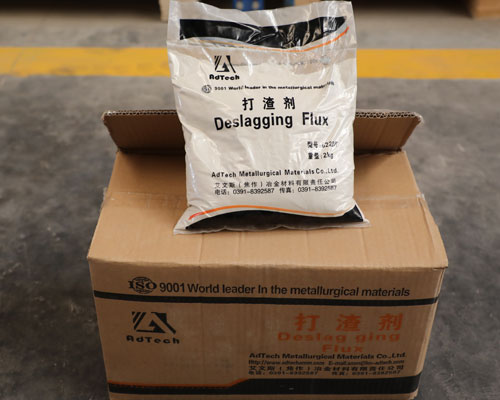

Deslagging Flux Manufacturer

AdTech slagging agent is white powdery fine particles. The main components are chloride and fluoride salts, and there are other compounds. After proper heat treatment and sieving out, the particle size is uniform. It can be sprayed with gas loaded in the refining tank, or directly sprinkled on the surface of the metal liquid for uniform stirring. They all can achieve the impurity separation effect. Deslagging flux is environmentally friendly and economical, and can meet the production of high-value-added, high-tech performance aviation, transportation, and other aluminum alloy precision casting. Such as computer hard disk, micron aluminum foil wool material, printing PS board base, can making material, jet turbine engine fan blades and other product castings.

Slagging Agent Uses

The slagging agent is used for slag layer on melt surface. The dosage is 0.25-0.50% of the weight of the metal, and the flux should not be excessive when it is added. If the amount is excessive, the heat reaction will be delayed. Sprinkle the flux on the surface of the slag, let the flux reach the metal temperature, and then stir it, and a layer of red slag will appear immediately. After the stirring stops, it will stand still for a period of time, and the slag will be removed after it has dried.

Each component in the flux reacts with oxides and slag through physical, chemical, and physical and chemical effects. The agglomerated slag is broken up, and the metal in the slag is pushed into the melt, leaving a dry, clean, granular slag with very low metal content. The flux can effectively complete this function in the range of 680-700°C.

The slagging agent can change the surface and interfacial tension between the metal melt and the slag body, reduce the bonding force between the melt and the slag body. It can effectively separate the metal and the slag, and improve the utilization rate of the metal. After adding the slagging agent to the metal melt, it can escape a large number of bubbles and play a certain role in stirring the melt. The entrained and adsorbed slag in the molten metal is fully turned and pulled to the surface of the molten metal. The slagging agent is beneficial to remove the slag thoroughly and ensure the melt is clean. It has the adsorption and melting ability to the slag body, which can fully purify the metal melt and reduce the metal pollution by the slag.