Oxide removal flux can clean the slag in furnace, wall, and bottom. The slag on the inner wall not only reduces the life of the refractories, but also reduces the volume of the furnace. The slag makes the circulation of molten aluminum difficult. The furnace cleaning agent realizes the continuous production of aluminum alloy and improves the quality and output. At the same time, oxide removal flux prolongs the service life of the furnace body, and reduces the labor intensity of manual. It is suitable for cleaning the kilns of aluminum alloy products.

Application of Furnace Cleaning Agent

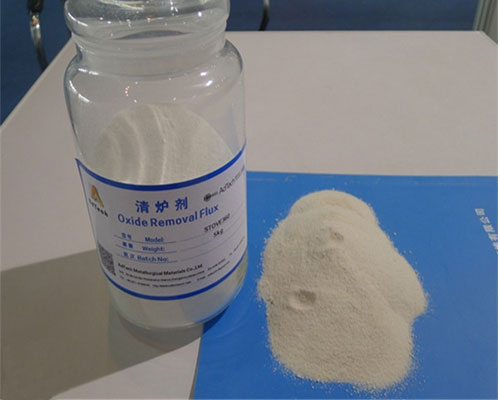

The furnace cleaning fluxes is white powdery fine particles. The main components are chloride and fluoride salts, and there are other compounds. After proper heat treatment and sieving, the particle size is uniform. Spray the oxide removal flux on the furnace chamber and furnace wall by refining tank.

How to Use Oxide Removal Flux

- Add 2.5-3kg of cleaning agent per ton of molten aluminum furnace.

- After the melting of the aluminum alloy in the furnace is completed, the furnace temperature will immediately rise to 850-950℃.

- Spray the cleaning agent onto the bottom of the furnace and the slag-attached part of the furnace wall, close the furnace door, and let it sit for 5-10 minutes.

- The furnace cleaning agent undergoes physical changes during the high-temperature process and instantly releases a large amount of heat energy.

- The temperature of the slag in the furnace increases rapidly, and the chloride in the cleaning agent melts quickly and reacts with it.

- Thereby reducing the melting point and viscosity of the slag in contact with this, to achieve the purpose of furnace cleaning.

- Open the furnace door, because the slag processed by it has achieved the separation of aluminum and slag.

- The slag has become quite loose, and gently stir the mixture of the cleaning agent and the slag for about 3-5 minutes to remove scum.