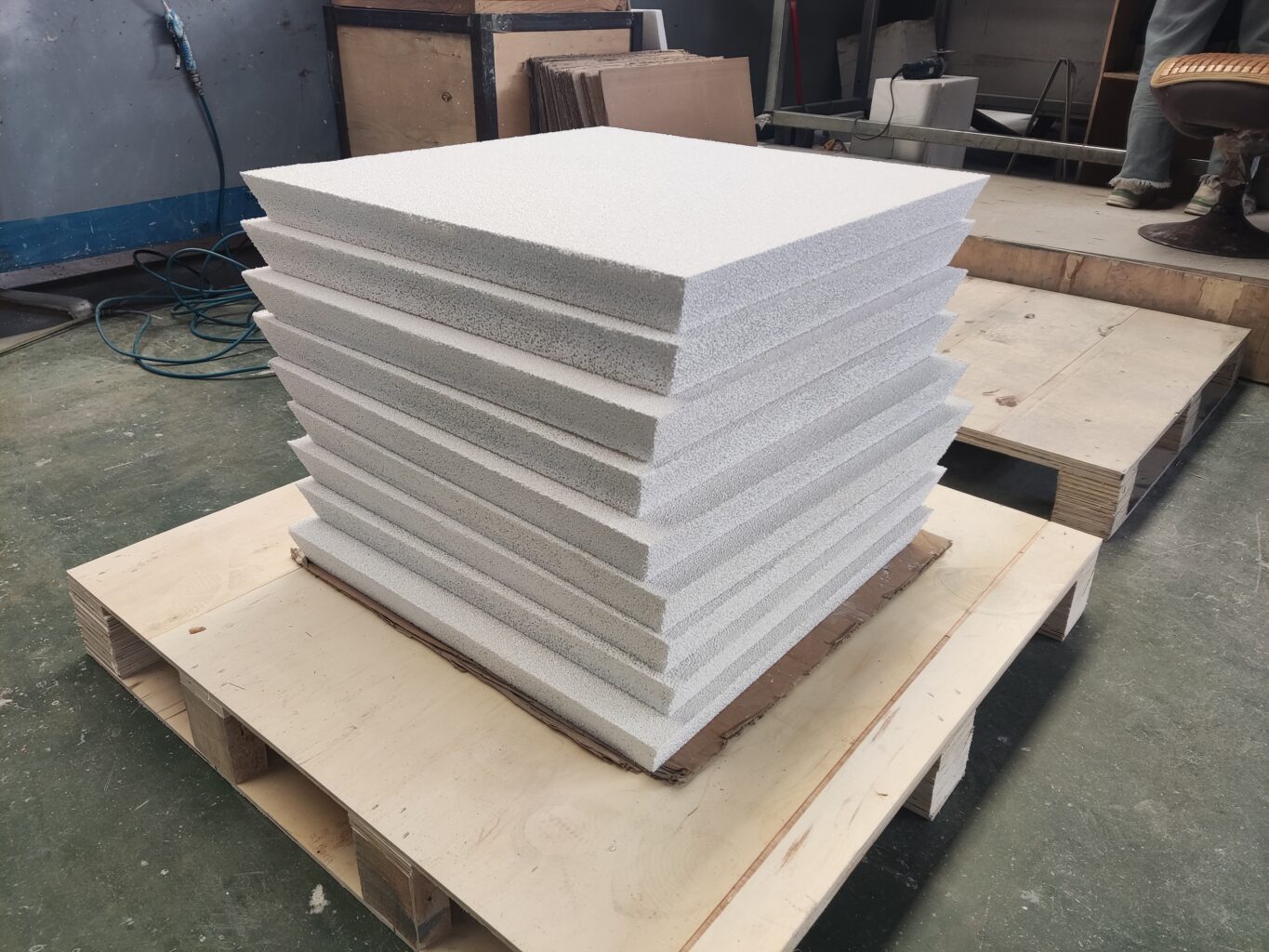

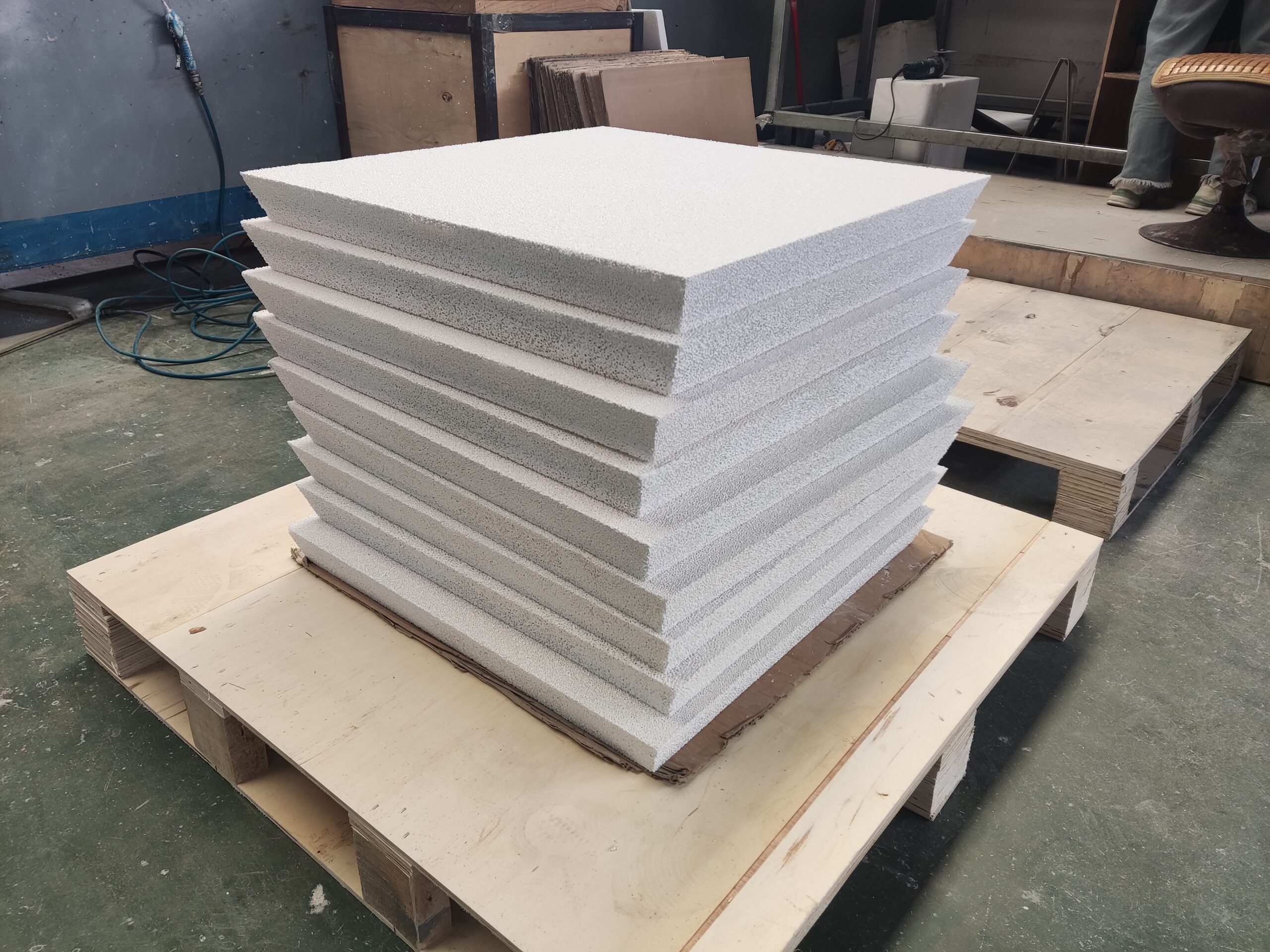

Aluminium Liquid Filter

The AdTech aluminum liquid filter uses a three-dimensional network structure and an organic bubble that communicates with the pores as a carrier, invading it into the thixotropic alumina material slurry, and adopting a square-corrected center-distance automatic extrusion process. The slurry is uniformly applied to the foam skeleton of the carrier and is baked and solidified at a high temperature of 1,180 ° C.

Alumina ceramic foam filter is installed in the CFF filter box for the impurity filtration of aluminum alloy liquid, and it can meet the high-value-added and high-tech aluminum alloy precision casting of aviation and transportation. Such as computer hard disks, PS board bases for printing, cans, jet turbine engine fan blades, and other products.

Aluminium Liquid Filter Description

A ceramic foam filter device has a peripheral surface surrounded by a gasket made of fibrous material and has a metal foil fixed to a gasket on the outer peripheral surface of the gasket.

Aluminum liquid filter according to requirements, wherein the metal foil is aluminum foil.

An adhesive fixes the metal foil to the gasket.

The width of the metal foil is slightly larger than the width of the gasket so that the gasket including its edges is surrounded by the foil.

The thickness of the metal foil is 0.01 to 0.10 mm.

The gasket is made of a soft, flexible ceramic fiber material.

The gasket is made of woven fiberglass cloth.

Aluminium Liquid Filter Advantages

1. It adopts the principle of adsorption to filter, which can effectively remove large inclusions in aluminum liquid and effectively absorb fine inclusions of small size;

2. No slag, effectively reduces the pollution of aluminum liquid;

3. Good thermal shock resistance and improved corrosion resistance to molten metal;

4. Automated assembly line production, three calibration procedures, accurate size, and more suitable for the filter box;

5. Improve surface quality, improve product performance, and improve the role of microstructure.