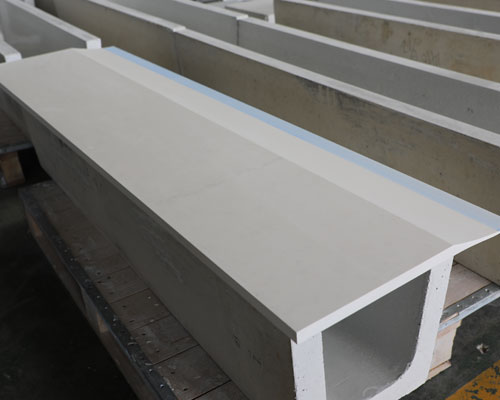

The structure and assembly of the feed caster tip is one of the most critical technologies for double-roll continuous casting and rolling. It is a component that distributes molten metal directly to the roll gap of the casting roll. Therefore, the distribution of the flow field and temperature field in the nozzle cavity directly affects the aluminum plate.

The difference between two-roll continuous casting and rolling and other continuous casting processes is that it is a comprehensive technology that integrates solidification and deformation. In particular, the outlet velocity of the high-temperature shallow aluminum melt in the nozzle cavity and the uniformity of the outlet temperature distribution determine whether the casting and rolling process can proceed smoothly and whether a high-quality cast slab can be obtained.

Feed Caster Tip Product Advantages

- Adopt nano-fiber composite material for integral molding, high-precision equipment processing, precise size control, appropriate density and rigidity.

- The key parts are reinforced with nano-coating, the surface of the hole is sealed, no delamination, good non-stick performance, and the corrosion resistance of molten aluminum is improved.

- The internal structure is reasonably designed with symmetrical flow channels to meet the requirements of liquid aluminum fluid mechanics.

- Good heat preservation, effective control of constant temperature parameters in the casting and rolling zone, it is the best choice for casting and rolling high-quality aluminum foil blanks.

- The deformation is small, the gap between the nozzle and the roller is easy to adjust, the surface quality of the aluminum foil blank is improved, and the white stripes and dark lines are effectively improved.

Instructions for Feed Caster Tip

Correspond to the drawing structure, cut and assemble to ensure that the nozzle plate is not damaged or cracked. Before use, place it in the oven, heat it at a constant rate for 2 hours to the target value, and keep the Roll-PH controlled temperature at 260°C for more than 5 hours to remove the adsorbed crystal water, then cool to room temperature and take it out No more than 2 hours (including vertical board time) to prevent the second entry of adsorbed water and ensure safe use and non-destructive installation.