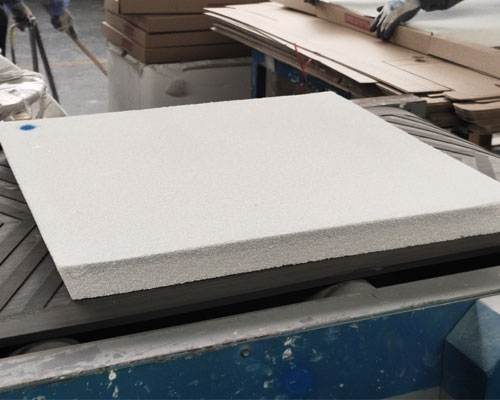

Aluminum foundry uses the right high-temperature ceramic foam filter materials will affect the productivity. AdTech specially designed alumina ceramic foam filters are made of the basic raw material aluminum oxide. They are manufactured with porosities varying from 10 to 60 pores per inch (PPI). Also, combo sets are made in 20-30 PPI and other selections are possible. Different sizes and custom-made filters are manufactured according to specifications.

Alumina has a relatively high coefficient of linear thermal expansion (8.0×10−6/° C.), and alumina monolithic shapes, such as ceramic foam filters, have poor thermal shock resistance due to the high thermal stresses generated by a combination of thermal gradients due to uneven heating and the high thermal expansion coefficient. During pre-heat and initial molten metal contact, the ceramic foam filter material may thermal-shock crack or spall and result in the release of filter material into the ingot or billet where it becomes an inclusion. In addition, when an alumina foam filter is restrained in a filter bowl during pre-heat and use, high lateral compressive stresses can be generated as a result of the high thermal expansion rate of the filter, leading to compression failure of the filter.

Aluminum orthophosphate (Al(H2PO4)3) is widely used as a refractory binder in the metals industry. It develops good green strength during drying at relatively low temperature, has low green shrinkage and develops good strength during subsequent firing. Aluminum orthophosphate is relatively inexpensive, widely available, and requires a relatively low firing temperature (1,100° C.) to obtain the final aluminum phosphate (AlPO4) bond. For these reasons, and because aluminum orthophosphate is relatively low cost, the material is widely used in the manufacture of ceramic foam filters for use in molten aluminum filtration.

The following are the ideal material requirements for ceramic foam filter materials:

1. High Thermal Shock Resistance—the material must not crack or spall during pre-heat or molten metal contact. The material should have low thermal expansion to minimize lateral compressive stresses while seated in the filter bowl.

2. Corrosion Resistance: The ceramic foam filter material should not react significantly in the intended application range (time, temperature, alloy content) and must remain non-wetted by molten aluminum and it’s common alloys.

3. Adequate bending and compressive strength

4. Economical to produce.

5. Filter material after use must be safe to handle and dispose.

6. Low Density or lightweight for the casting pit operator to easily handle.