The development of cast aluminum filter materials has promoted its wide application in the metallurgical industry. Cast aluminum filters are usually used to create a three-dimensional network structure, and organic foam is used as a carrier for interconnected pores. The ceramic foam filter is a special type of porous material with interconnected porous structures. The porous microstructure provides a large filtering surface area, which is suitable for high collection efficiency.

Good chemical resistance, resistance to sudden temperature changes, and high thermal stability at high temperatures provide the best conditions for filtration during the casting process. The ceramic foam filter can be used in the filter box of the gating system and poured directly on the filter. Ceramic foam filters are produced using common imitation technology (polyurethane polymer sponge method).

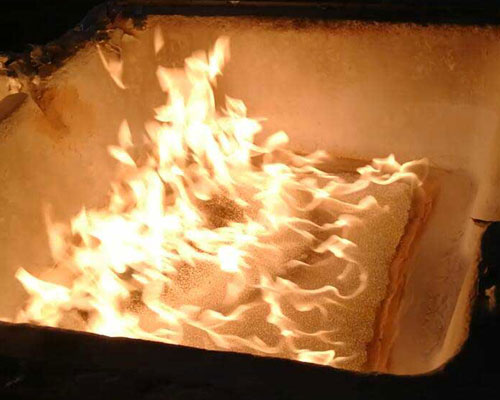

The method includes immersing the polymer sponge in the ceramic slurry, then removing the excess slurry, drying, pyrolyzing, and burning off the polymer substrate, leaving a cross-linked porous structure, and keeping it under suitable atmospheric and temperature conditions. Sintering is performed below for final densification.

The foundry should determine the pore size of the filter according to the quality requirements of the casting and the number of inclusions in the molten aluminum. The size of the filter is determined according to the pouring speed and pouring weight. After removing the impurities in the cast aluminum filter, the quality of the ingot can be significantly improved, and the scrap rate can also be reduced.

Cast aluminum ceramic foam filter can effectively filter non-metallic inclusions and impurities in molten metal. The ceramic filter can adjust the turbulence and provide laminar and stable melt flow in the casting system, thereby reducing entrained gas, pinholes, mold corrosion, and sand defects. Therefore, filtration improves the microstructure uniformity, mechanical properties, processability, surface quality, and performance of the final product. Generally, ceramic filters help to produce higher quality products through a simple casting system, and reduce production costs by reducing casting defects and rejects.