Foam Ceramic Filter Materials have properties such as high strength and hardness, good plastic toughness, corrosion resistance, and high temperature resistance.

Because the casting temperature of the casting alloy is different, the foam ceramic filter with corresponding fire resistance performance should be selected. According to different casting alloys and pouring temperature, choose different foam ceramic filter materials principles: steel castings generally use zirconia filters, cast iron and copper castings generally use silicon carbide filters, and aluminum alloys are generally used Alumina filters, magnesium alloys generally use magnesia filters.

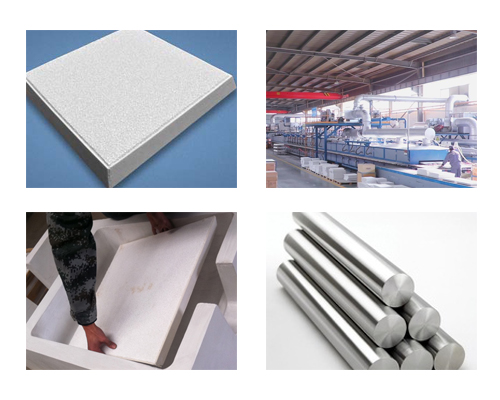

Our Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. AdTech alumina foam ceramic filter can effectively remove large-size inclusions in molten aluminum and can effectively adsorb small-size inclusions. They are manufactured with porosities varying from 10 to 60 pores per inch (PPI). Also, combo sets are made in 20-30 PPI and other selections are possible. Different sizes and custom-made filters are manufactured according to specifications. The effect of reducing aluminum slag pollution is obvious. Good thermal shock resistance improves the corrosion resistance to molten metal. Automatic production line, accurate size, more suitable for CFF filter box.

Generally speaking, the installation and use of ceramic foam filters need to pay attention to the following aspects:

1. The correct choice of ceramic foam filter: The size and specifications of the filter plate must consider the specific type of metal filtration, the maximum level, the total amount of filtration, and the cleanliness of the original aluminum liquid.

2.The pretreatment of melt filtration cannot be ignored: such as normal furnace and holding furnace slagging and furnace cleaning.

3. Especially the online degassing device is still necessary, because it can not only reduce the hydrogen content in the melt, but also remove some non-metallic inclusions.

4. The ceramic foam filter should meet the high temperature CFF filter box: suitable for sealing, can prevent the gap between metal filtering and entering the box, and also avoid the foam filter plate from being too light and failing from the aluminum liquid.