The aluminum casting tip and nozzle directly feed the aluminum melt into the double-strip continuous caster, it is the main component of the high-throughput aluminum continuous casting and rolling process, which will affect the production efficiency of the process.

Through the study of the blocking mechanism of the Aluminum Casting Tip and Nozzle, the structure in the blocked nozzle cavity is composed of three layers: the reaction layer, the slag layer and the metal layer. Inclusions with a size of less than 3um generally have little effect on the performance of alloy products, but they will aggravate the slagging of the casting nozzle, cause the nozzle to block, reduce the production efficiency of high-throughput continuous casting and rolling aluminum alloy products, and increase economic costs. At the same time, due to the characteristics of the high-throughput continuous casting and rolling process, these small inclusions will easily gather together during the casting process, causing segregation of the cast plate and affecting the performance of the product.

Through tensile experiment and fracture analysis, it is concluded that with the increase of the inclusion content, especially when the inclusions are on the edge of the sample, it is easy to form the source of cracks, resulting in high-throughput continuous casting and rolling aluminum alloy rolling sheet alloy tensile strength And the elongation becomes worse.

In the high-throughput aluminum continuous casting and rolling process, the control of inclusions is very strict. It is necessary to perform online degassing and filtering of the aluminum melt. In-furnace refining or online degassing and filtering remove most of the non-metallic solid inclusions. The cleanliness of the aluminum melt before casting is relatively high, and the content of non-metallic solid inclusions in the aluminum alloy melt is extremely small.

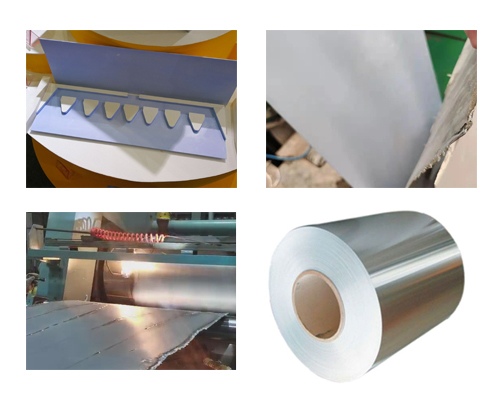

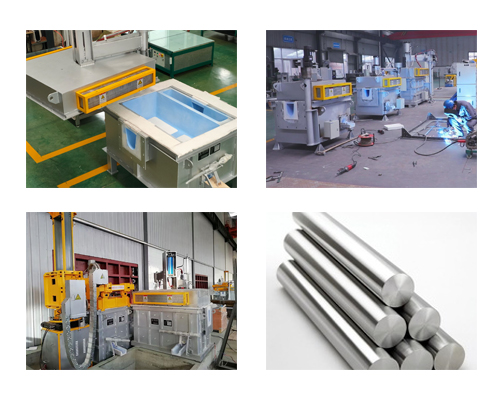

AdTech supplies Fluxes, Degassing Unit, Filter Equipment, Ceramic Foam Filter for molten aluminum purification. We also supply caster tips and headbox for the continuous casting and rolling process.