AdTech fluxes for molten aluminum refining are fine white ( gray) powder shaped, the main components are chloride and villiaumite, and other chemical compounds. Fluxes are designed for degassing, cleaning, grain refining of molten aluminium alloys, and other purposes. Fluxes are usually added during the melting, holding, or degassing of aluminium to furnaces, crucibles, ladles, or other aluminium vessels. Flux raw-material quality, addition method, and product form can all affect efficiency. A flux recipe varies depending on its purpose and other process variables. Refining fluxes are widely suitable for the refining of casting Aluminum / Alloy in the reverberatory furnace and holding furnace.

Put the flux into powder spraying equipment, it will spray the flux into molten aluminum twice averagely under the action of nitrogen or argon, make the nozzle close to the furnace bottom and stir evenly, keep the flux is well contacted with molten aluminum then use nitrogen or argon to refine 20 minutes in furnace bottom, after physical and chemical function, many minute bubbles formed. The bubbles separate hydrogen atom and slag from molten aluminum. After that, the deslagging and purification completed. AdTech fluxes can form low melting, high fluidity compounds within molten metals. It can generate anions capable of reacting to form desired reactants. In addition, fluxes also can absorb, agglomerate or float reaction products.

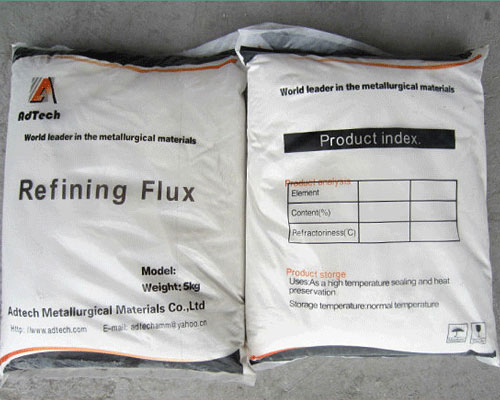

AdTech Fluxes

In general, AdTech fluxes include the following categories:

- Covering fluxes can provide physical barriers to oxidization.

- Cleaning fluxes can remove oxides suspended in the melt.

- Drossing fluxes can promote separation of the aluminium from the dross layer.

- Refining fluxes can react with certain metallic elements in the aluminium, such as Mg, Ca, Li, Na, K.

Refining Fluxes Advantage

- Good Liquidity, good performance in deslagging and degassing

- Good purification, less pollution, less dosage, low cost

- Easy separation of aluminum and slag

Pingback:Aluminum Alloy Degassing Agent – 站点标题