Aluminum is guided into the casting machine from the melting furnace through the launder and storage tank. Launders with steel sleeves are lined with refractory materials, and they are open launders or launders with lids. The AdTech High Quality Launders are suitable for installation at an inclination, and the melt flows through gravity. In order to transport and meter the melt, a storage tank is also required, such as a stable storage tank. The melt is poured into the stable storage tank from the melting furnace, so that the molten metal is introduced into the casting launder, and the movement of the molten metal is stabilized in the stable storage tank. In addition, intermediate tanks and metering tanks are usually required. When increasing the capacity of casting equipment, it is necessary to make the melt launder longer, resulting in larger cooling and solidification problems of aluminum in the launder than before. When aluminum solidifies in the launder, it prevents the melt flow.

To prevent solidification, the molten aluminum is heated to a sufficiently high temperature in the melting reactor, so that the temperature of the molten metal keeps the metal flowing and also heats the launder until the temperature of the casting machine. The casting launder is lined with refractory material, and its loss is directly proportional to the temperature of the metal being transported: the higher the temperature of the melt, the faster the launder lining wears.

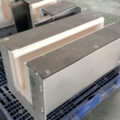

AdTech High Quality Launders

The lining of the AdTech High Quality Launders is made of high-quality A14 material cast in a high temperature in the sintering furnace, which has the characteristics of excellent erosion resistance, impact resistance, cold shock resistance, non-stick aluminum, no chemical reaction with aluminum, and small thermal expansion coefficient. It keeps its shape stable at working temperature, and does not absorb moisture, and does not generate gas to the aluminum melt. It is durable and does not pollute the aluminum melt.

Under the conditions of using in accordance with the specified process, the temperature drop per meter of the flume is not more than 3 degrees Celsius, and the service life of the lining is not less than 18 months.

The lining of the flow channel adopts a combined structure. The liner of the DC channel is usually 600mm/node. At the same time, it provides elbows with the same cross-sectional size and three-way diameter reduction.